Background: what are high power ZnSe beam splitters? Some Beam splitter theory.

High power C02 lasers are highly useful in multiple applications, including marking and perforation of textiles, paper and plastics, skin treatments and even glass welding. With increasing laser power, such laser systems can no longer be point-by-point scanned at sufficient speed to fully utilize the laser energy, requiring multi-beam solutions to increase throughput.

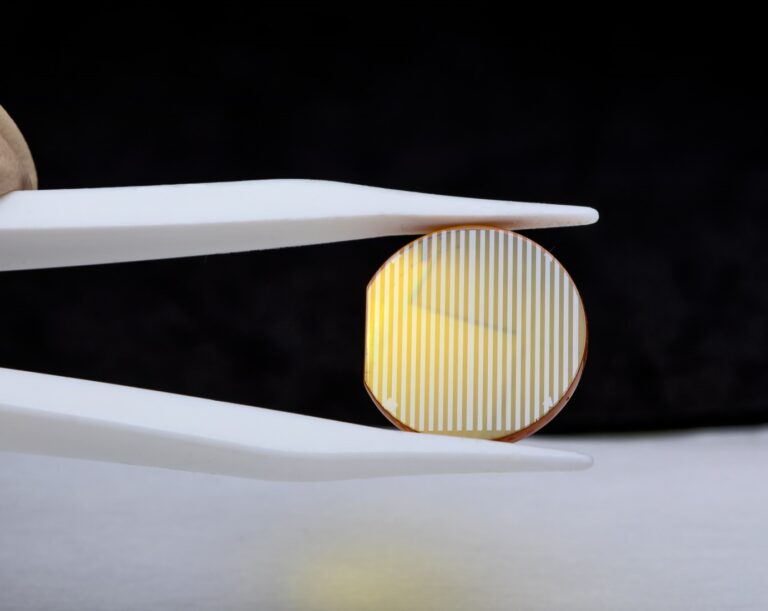

Holo/Or’s ZnSe beam splitters are a leading solution for this challenge. A beam splitter is a Diffractive Optical Element (DOE) that splits an incoming laser beam into a fan of beams with controlled separation angles. This is achieved by creating a grating like, periodic phase structure on the surface of the beam splitter DOE, resulting in a purely transmissive phase based element (no absorption/ reflection) that is suitable for the high power lasers. Specifically, for CO2 lasers ,Holo/Or produces the laser beam splitter DOEs on a ZnSe substrate. ZnSe is a well known substrate in high power MIR applications, and with laser grade AR/AR coating Holo/Or laser beam splitters can withstand KW level lasers without harm.

The beam splitting of a ZnSe beam splitter can be along a line (1-D splitters), or into a grid (2-D splitter), including square, hexagonal, or rectangular dot matrix arrangement. Since the beam splitter phase is periodic, ZnSe beam splitters are insensitive to beam alignment or beam size, and are thus easy to integrate into existing CO2 laser systems

ZnSe beam splitters for laser perforation applications.

Znse Beam splitters are often used in perforation system, where multiple holes need to be rapidly drilled in a thin material, typically paper or polymer, often for filter/ selective membrane production. The input CO2 laser is typically split into a line of spots, with the material to be perforated moving perpendicular to the line of spots using a roller or some other rapid linear motion method.

For these application, the presence of undesired higher diffractive orders is often disruptive, as they may result in aesthetic effect to the filter material. A solution offered by Holo/Or are high efficiency ZnSe beam splitters, which have suppressed undesired orders. Such a laser beam splitter can be integrated into existing laser head setups and boost the perforation throughput significantly.

Laser skin treatment with CO2 laser splitters.

Laser skin treatment is one of the first applications of CO2 lasers, from the start of the laser medical aesthetic industry , and is still highly relevant and in broad use today. The CO2 laser radiation is strongly absorbed in water , thus it has limited penetration and with short ns pulses can deliver targeted thermal energy to relevant treatment areas. To cover large areas and enable speedy treatment, the laser beam is often split into a two-dimensional matrix of spots using a ZnSe beam splitter. This matrix typically covers ~10X10mm on the patients skin, making area coverage easy and fast. For these applications, stringent control of the zero order so that it is weaker than desired orders is critical, and this is where Holo/Or laser beam splitters are appropriate.

Parallel surface treatment with CO2 lasers.

In some industrial processes, a CO2 laser beam is used to mark or bleach a certain material, typically textiles. To increase the throughput of such laser marking machines, ZnSe beam splitters are often used to create several separate spots with a single laser head. This is a significant cost saving compared to a multi-head approach, as ZnSe refractive optics are typically high cost and multiple head require multiple optics. The beam splitter function of the ZnSe Doe can be combined with other functions such as flat top line shaping, allowing the laser system to cover several separate areas with uniform laser power.

ZnSe beam splitters are critical components that allow integrators to harness the full power of their CO2 lasers. As a lead beam splitter manufacturer, Holo/Or Ltd offer multiple standard ZnSe laser beam splitters. For support with your Co2 laser application, Contact us and we will be happy to support you, relying on our long experience in the laser beam shaping industry.

TL; DR - Q&A summary

1. What is an ZnSe beam splitter?

ZnSe power beam splitter is a diffractive optical element that splits an incoming beam to multiple beams with precise separations and power ratios. This element is a monolithic window with the structures etched in the ZnSe.

2. Why use a ZnSe beam splitter with high power CO2 laser?

In many CO2 laser applications, it is impossible to scan point by point fast enough to utilize the full laser power. A diffractive laser beam splitter creates an array of spots that spread the laser energy, enabling increased throughput without resorting to more than a single laser head.

3. What are the advantages of a diffractive ZnSe beam splitter for Co2 applications?

Beam splitters have absolute angular accuracy, high laser damage thresholds and flexibility in design to create any configuration of spots required. They are a single, flat passive component that can create thousands of spots, as needed, and have no sensitivity to the polarization of the incoming laser. All these make ZnSe beam splitters very easy to integrate into CO2 laser setups.

4. What are the common CO2 laser applications that use ZnSe beam splitters?

ZnSe laser beam splitters are used in filter perforation, laser marking/surface treatment, aesthetic skin treatments and many other applications.

5. Can I combine beam shaping of the spots with laser beam splitting in a single ZnSe beam splitter?

Yes, diffractive ZnSe beam splitters can have beam shaping functions added to the same surface, for example shaping the spots to flat top lines.