Introduction

Over 60 years ago, a scientific breakthrough was the catalyst for the discovery of the first laser. Since then, the use of laser devices has been growing in research applications, and in recent years, industrial and commercial applications have been taking up this technology as well. Lately, that growth trend has rapidly increased thanks to laser availability and a sharp decrease in laser price-per-Watt.

A Typical laser source generates a near Gaussian beam profile with the maximum energy at the center and a moderate energy decay towards the edges. This intensity profile is not ideal in many applications, and so many research and development engineers seek beam shaping technologies to achieve their desired laser beam shape and intensity profile.

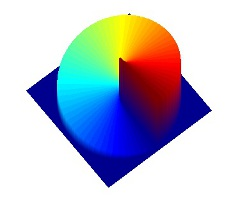

One such desired shape is a ring-like donut shape with controlled ring intensity and an energy hole in the center, which is the output shape of a vortex beam.

An optical vortex beam can be best achieved using a single diffractive vortex phase plate, also known as vortex lens (VL).

Diffractive Vortex phase plate

Vortex beam generation can be performed using a diffractive optical vortex phase plate, which is a unique optical element composed of a helical or spiral phase, or “staircase” step structure (hence its other name “Spiral Phase Plate” or SPP). This sort of vortex phase structure adds orbital angular momentum to the beam, effectively “pushing” the energy out from the center, in a manner similar to water spinning around a sinkhole that generates a whirlpool being pushed to the sides. This results in the generation of a donut mode, regardless of incoming beam polarization, merely through the orbital angular momentum of the light. This is in contrast to liquid crystal-based vortex phase plates, that manipulate the spin angular momentum.

The diffractive vortex plate requires a high-quality collimated TEM00 Gaussian input beam and converts it to a TEM01 axially symmetric mode, with advantages to working with large input beams on both lower sensitivity to alignment aspect and smaller donut spot size at the output.

More than a single staircase structure can be fabricated on the diffractive surface, with the number of such staircases corresponding with the topological charge m. Each such staircase structure’s etch depth is a function of the design wavelength and the substrate’s optical index.

The main effects of the different topological charge are:

- The higher the topological charge, the higher the angular moment of the vortex beam is by a factor of m.

- The higher the topological charge, the larger the donut ring intensity profile is by a factor of m.

Advantages of Vortex phase plates

Vortex phase plates have several advantages compared to other beam shaping methods:

- An optical vortex beam is self-healing; thus, it is not sensitive to clipping, requiring clear apertures similar to a gaussian beam. This is not the case for beam shapers, where often the clear aperture required is X2 the beam diameter.

- The vortex phase works for all input beam sizes – the resulting donut is scaled with input beam size, in a manner similar to the gaussian beam. There is no need for a well-know input beam diameter.

- When scanning vortex laser beams, the integrated energy profile across the scan line (i.e., the trench energy profile for ablation) is flat- top, unlike the case with a gaussian laser beam. This is true even for low topological charges, including m=1, enabling relatively narrow scanned lines with good uniformity across the line profile.

Vortex beam applications

Vortex laser beams are typically used in research applications mainly in the life science disciplines. One such application where vortex beams pose a distinct enabling advantage is super resolution imaging with STED microscopy, in which the depletion laser is shaped into a vortex beam before focusing it with the excitation laser by the objective.

Another application utilizing the vortex phase plate is optical tweezers, in which a highly focused laser beam is used to hold and move microscopic and sub-microscopic objects like atoms, nanoparticles and droplets, in a manner similar to tweezers. The donut shaped vortex beam provides the advantage of trapping the particle inside the donut hole at the focused beam waist.

Other known applications using vortex lenses include:

- Solar coronagraphs (astronomy)

- Lithography

- Quantum optics

Holo/Or offers a wide variety of vortex phase plate DOEs. to calculate the ring and hole diameter of the vortex plate, Holo/Or created this optical vortex calculator to aid our customers in choosing the part fitting their needs.

TL; DR - Q&A

What is a vortex beam?

A vortex beam is a ring-like (donut) shaped beam with controlled ring intensity and an energy hole in the center.

How to generate a vortex beam?

The most efficient way to generate a vortex beam is to use a diffractive vortex phase plate, which is a unique optic that has a helical spiral staircase structure.

What are the applications for vortex beams?

Vortex beams are mainly used in life science applications such as super-resolution microscopy, optical tweezers, and more.