A tophat output beam is characterized by having a uniform focused intensity distribution with a well defined shape and size, and with sharp edges. In this article you will learn how to obtain such an illumination profile with your laser beam

A tophat output beam is characterized by having a uniform focused intensity distribution with a well defined shape and size, and with sharp edges. In this article you will learn how to obtain such an illumination profile with your laser beam

A tophat output when referred to an optical system including a laser beam, describes the energy distribution of the beam after going through a certain medium along the optical path. The top hat energy can be generated either directly onto the working plane or onto another component within the system.

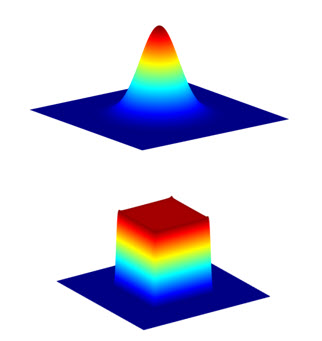

A typical laser beam, when exiting the laser source, would have a Gaussian distribution with the maximum energy at the center and a continuous energy decay until no energy along the beam edges. If imaged on a focus plane, it will show as a very bright spot at the center of the beam with the brightness level lowering the further from the center, until no energy at all. The medium applied to alter the intensity profile from the Gaussian beam into a tophat output intensity profile is known as a laser beam shaper, or to be more specific, a top hat beam shaper.

A top hat energy distribution, unlike the Gaussian beam, has a well-defined size and shape with uniform intensity over the entire spot, with sharp edges and no energy outside the spot area, as opposed to the continuous decay of the Gaussian beam. When looking at the output beam intensity profile, it looks somewhat like a top hat, and therefore – its name.

There are several techniques to manipulating a Gaussian beam into a tophat output, some of them designed for use with single mode lasers while others are suited for multi mode lasers, the latter are sometimes referred to as “beam homogenizers” or “diffusers”. Choosing the wrong type of beam shaper may result in either a speckled pattern or simply a low uniformity pattern with high p-v values. The most commonly used top hat beam shaper for highly coherent single mode lasers is the diffractive beam shaper on which this entry will focus.

A diffractive top hat beam shaper, also known as flat top or analytical beam shaper, is an optical window-like component used to transform a near Gaussian beam (typical M^2 values <1.5 ) with a known beam diameter, into a highly uniform focused spot with well-defined size and shape and without any speckles. The spot shape can be of any geometrical nature, such as round, square, rectangle, line etc. A typical optical setup containing a top hat beam shaper will include a focusing lens right after it, however the diffractive pattern can also be fabricated into the lens itself creating a focal beam shaper which does not require an external lens.

The uniform spot achieved by integrating a top hat beam shaper enables equal surface treatment, preventing over or under exposure of areas. This characteristic of the tophat output has many useful industrial applications, mainly in micro machining and other material processing applications where a specific energy threshold is required and process accuracy is essential. Some of the applications widely using diffractive top hat elements include:

And many more, in industries such as microelectronics and PCB fabrication, micro LED laser lift off, battery production and more.

On top of the uniform treatment, the use of a top hat laser beam enables increased system throughput as the tophat output can be designed to the specific required process threshold and so optimize the use of the available laser power.

The term “tophat output” refers to the intensity profile of a laser beam once it has transferred through a laser beam shaper. The achieved distribution is characterised by being a uniform focused spot with a well defined shape and size, and with sharp edges.

A top hat laser beam can be generated using a laser beam shaper. There are several methods to shape the beam, and the most suitable solution should be chosen based on the input beam parameters and the system requirements. For highly coherent single mode beams, a diffractive beam shaper is the most commonly used solution.

A top hat beam is characterised by a well defined focused spot shape with sharp edges and a uniform energy distribution. These characteristics allow equal exposure of a very accurate desired treatment area. Moreover, the top hat beam shaper can be designed to a specific process threshold and so enable optimized energy utilization.

Design and Manufacture of Diffractive Optical Elements for high power lasers

DESIGN & MANUFACTURE OF DIFFRACTIVE OPTICAL ELEMENTS

Want to discuss your project with us?

Leave your details and

we’ll reach out shortly!