Top Hat beam shapers enable cutting of thin films, such as OLED films, with reduced HAZ and improved efficiency

Heat effected zone reduction with a Top-Hat Beam shaper

The rising demand for organic light emitting diode (OLED) screens resulted in a search of better laser-based film cutting solutions that require higher power and better processing quality.

One of the problems that manufacturers are currently facing is reducing the heat-effected zone (HAZ) next to the edges of the cut. One solution that was offered to mitigate this problem is the use of short pulsed CO2 lasers to reduce HAZ.

Another possible solution is using a Top-Hat beam shaper in order to reduce the width of the edges of the laser treated area , thus reducing the HAZ.

What is a Top Hat Beam Shaper? Top-Hat beam meaning

A Top-Hat beam shaper is a diffractive element which is designed to change the energy distribution of Gaussian single mode beam to a more desirable distribution. These elements are mainly used to shape the output beam to a flat, uniform distribution with sharp edges. Top Hat beam shaping can create spots with various shapes, including line, round, square or a rectangle spot, all with flat top intensity. Elements with custom shapes can also be designed and manufactured.

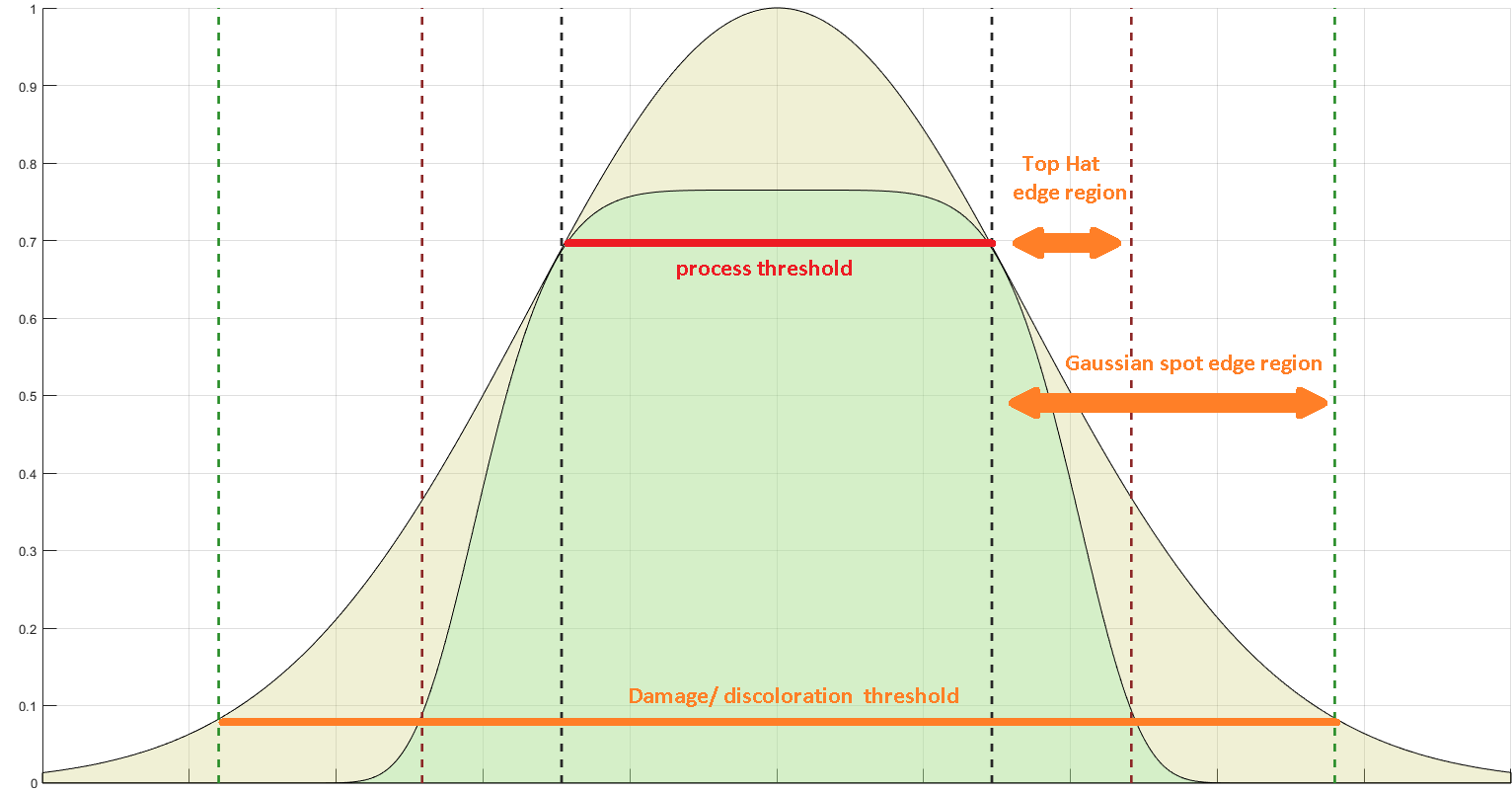

Compared to a gaussian distribution with the same threshold area size, the edges of the Top-Hat beam profile are much sharper. This means that a smaller area will be exposed to the beam and HAZ should be reduced.

Since Film cutting is a threshold processes it is characterized by a certain threshold laser energy density that must be reached for a certain area to be processed. For such processes, a flat top energy distribution has advantages that make it highly desirable.

Unlike the Gaussian beam profile of single mode beams, where the width of the Gaussian spot (above the process threshold) is directly proportional to the energy, a top hat energy profile is characterized by having almost no dependence between the pulse energy and spot size above the threshold. This means that the same results can be achieved by using lasers with lower maximum pulse energy, compared to an equivalent width cut done by a Gaussian energy profile . Lower energy means that there is much less energy in the edges, and less HAZ , when using a top hat laser beam shaper to get a flat top beam.

Integration of diffractive top hat beam shapers into laser film cutting

Diffractive top hat beam shapers are often easy to integrate into existing laser machines for film cutting applications. Such machines often create the cut path by either scanning the head with a stage or by using a galvo and F-theta setup to steer the beam. In both case, getting a top-hat beam laser beam profile using one of Holo/Or’s DOEs is simple, as you only need to integrate a single, flat, window- like component into the existing optical path , making integration straightforward.

The main requirements for successful use of the top hat laser shaper are:

- Single mode input beam, M2<1.3 (typica or most CO2 lasers)

- Beam diameter +-5% of designed beam shaper input diameter

- Clear aperture of scanner, lens and all other optics at least X2 times the input beam size.

To further aid integration, Holo/or has written an installation guide and application notes.

TL;DR - Q&A summary

What is a top hat beam shaper?

A top hat beam is a diffractive flat optical element that receives a single mode gaussian beam as input and outputs a flat intensity spot with a controlled shape (square, rectangle line or round image).

How can one reduce the Heat Affected Zone (HAZ) in my process?

HAZ can be reduced by exposing less edge area to the laser and decreasing the peak laser power – Top Hat beam shapers can be utilized for both purposes.

why can a flat top distribution help decrease HAZ for laser film cutting?

Since most cutting processes are threshold processes, less energy is “wasted” when using a flat top intensity and the same results can be achieved using less energy. This means that relatively, there is less energy in the sharp edges of the shape, thus less HAZ.

How Can I integrate a Top Hat Beam Shaper to my system?

the top hat beam shaper can be easily integrated to most systems since it is a single, thin element which can be placed almost anywhere along the optical path. Beam size and centering are the main tolerances.