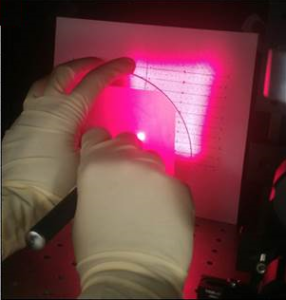

Structured light diffractive optical elements (DOE) are specially designed to split or shape a single laser beam to cover a large field of view.

By upgrading our production facilities, Holo/Or now offers high-angle, high-quality, high-efficiency Beam Splitters and Beam Shapers DOE for both low and high-power applications ranging from mW to KW range.

Our DOE are made of either UV-grade Fused Silica, or low cost option such as polymer on glass or injection molded plastic. The main plastic types are: Polycarbonate, PMMA, Zeonex and Zoner.

Typical applications include structured light 3D sensing, LIDAR and light projection.

Holo/Or is happy to launch this brand new High-angle Diffractive Optical Elements (DOE) product line to meet our customers’ demands.

SPECIFICATION RANGE

| Possible multi-spot (dot / line generator) patterns | Random spots, Spot array (1xM), Spot matrix (MxN), Multi-line, Grid |

| Possible diffuser (homogenizer) patterns | Circle, Square, Rectangle, Line, Custom |

| Wavelength | 266 - 2200 nm |

| Full angle @ 850 nm | Up to 80x80 degrees |

| Zero Order | Angle dependent, can be optimized for eye-safety |

| Material | UV grade fused silica, Polymer on Glass or Plastic |

| Dimensions | From 2x2mm up to 150mm diameter (square or round) |

Beam Splitter

Target DOEs

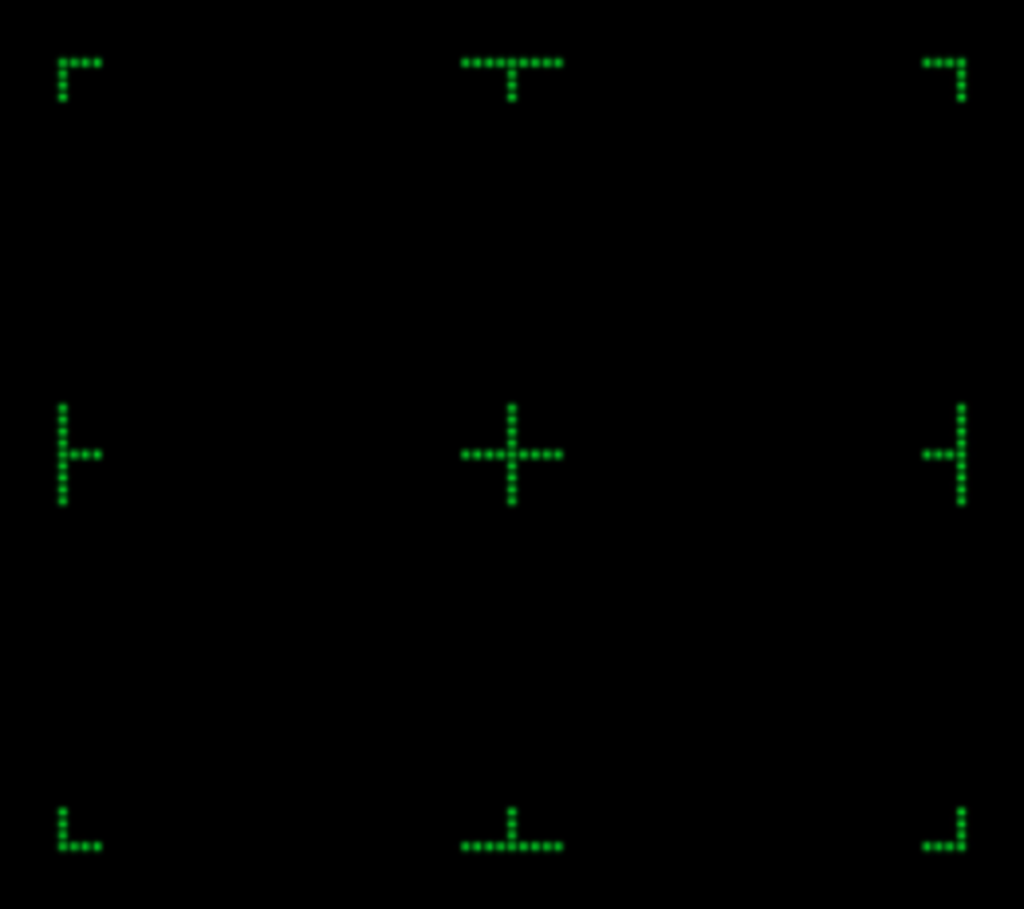

Multispot DOEs with the remark “target” is an element that produces a number of spots building a typical target, refer also to below image.

Random DOEs

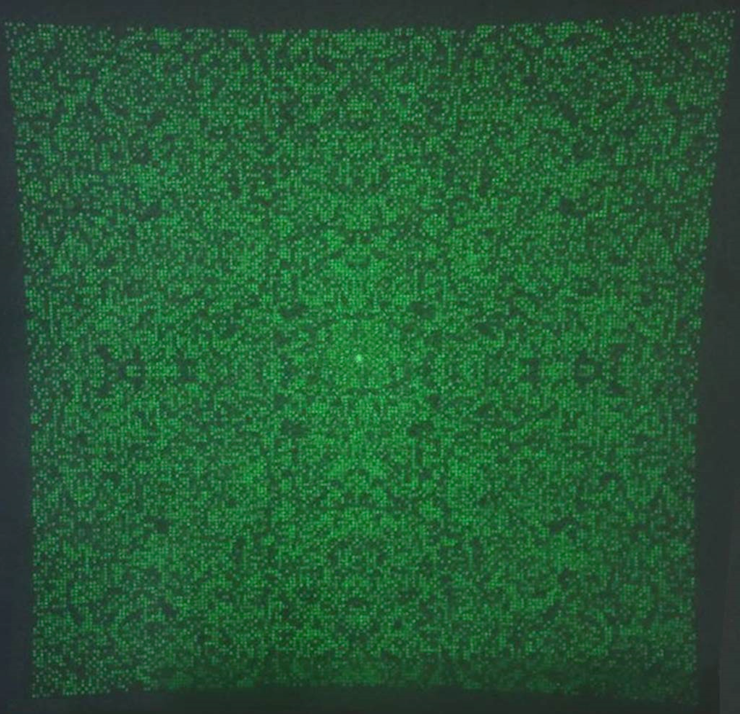

Multispot DOEs with the remark “random” have a random pattern of spots, when 50% of the dot matrix are potential spots and will be “on”, and this is determined by a randomizing algorithm.

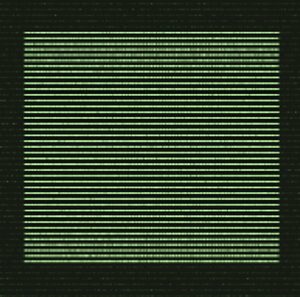

Standard MS DOEs

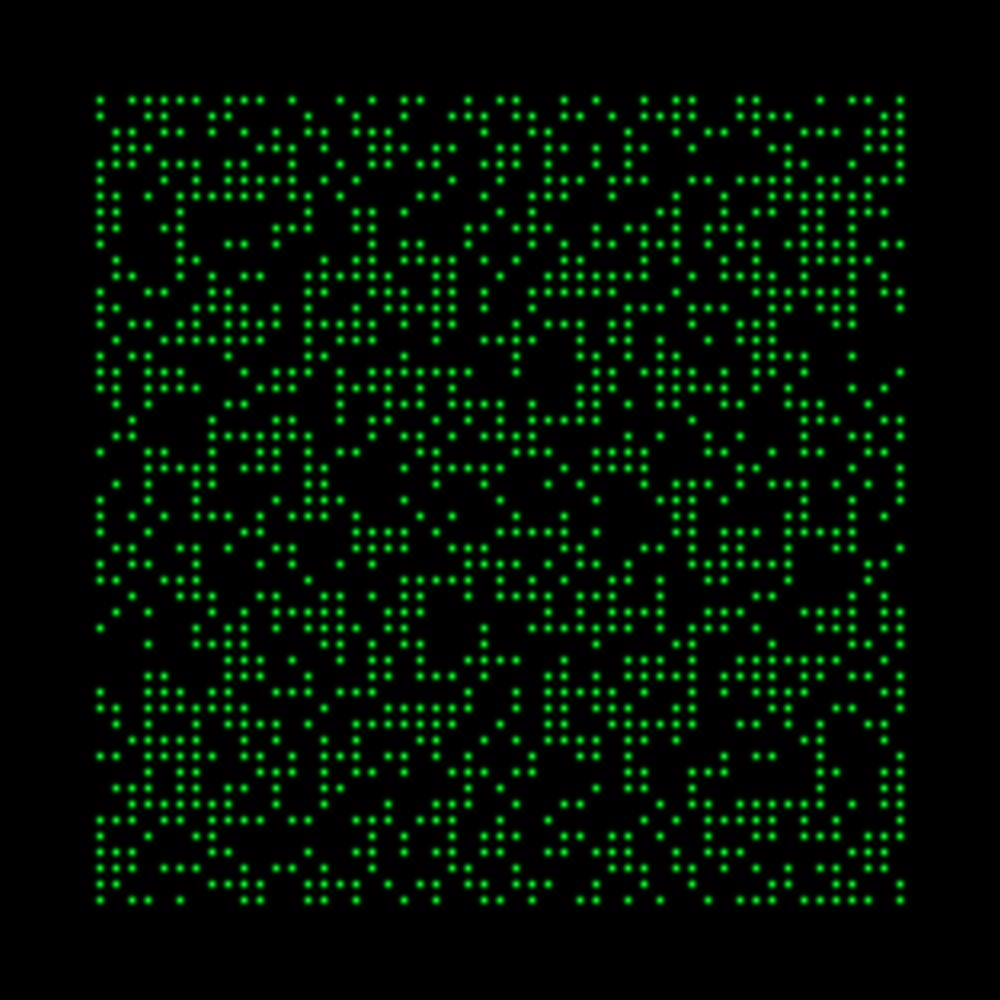

Multispot DOEs without any additional remark, show a homogenous distribution of the spots, as shown in the image below:

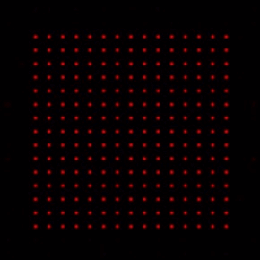

Diffuser / Homogenizer

For structured light solution, please contact us and provide the following details

If you are interested in custom DOEs, please provide the following data:

- Description of application

- Wavelength

- Beam definition (diameter, input mode, divergence)

- DOE dimension – if some specific values are needed

- Working distance

- Requested output shape at working distance

- Special needs (high efficiency, high homogeneity, AR coating)

- Quantity for samples and serial production