Background: what is a phase plate?

A phase plate is a diffractive optical element that superimposes a certain pre-designed phase profile on an input laser beam. Such a phase profile can be binary, i.e create a half-wave delay between certain areas of the phase plate, or it can be continuous, and reach up to a full wave delay. This phase profile transforms the laser intensity profile at the far field (i.e lens focus) to a different profile.

In cases where the phase is periodic, such as in the case of a phase grating, the intensity becomes multiple diffracted orders with controlled separation angles. This is what we at Holo/Or call diffractive beam splitters or gratings. In cases where the phase is not periodic, various beam shaping effects occur depending on the phase profile superimposed by the phase plate.

Phase plate shaper types

For phase plates that shape the light, one of the most useful functions is mode conversion. Single mode lasers have a gaussian beam profile that can be focused to a gaussian spot. Often, better process results can be achieved by energy distributions that are different from a simple gaussian.

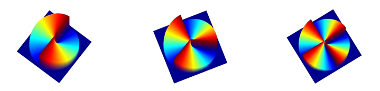

Binary phase plates, such as our mode converters, can create various analytical modes that have different intensity shapes. These are various Hermite-Laguerre modes of different orders, equivalent to TEM01, TEM11 and higher.

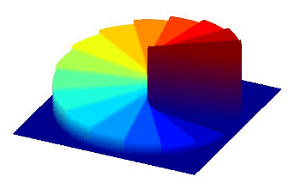

Other, Vortex modes can be created by special phase plates called spiral phase plates, or vortex phase plates. These are multi-level phase elements whose phase is similar to a circular staircase, that generates a vortex mode with a certain topological charge. For every topological charge, the mode creates a different donut shape at focus, with a hole in the middle where intensity drops to zero.

Advantages of spiral phase plates for high power laser beam shaping

Using a vortex phase plate offers many advantages to high power laser application developers and integrators. These include:

- Scalable shaping – by changing input beam size, the phase plate generates different donut sizes, with linear scaling of all shape dimensions when beam diameter is changed.

- Robust shaping – the vortex mode is very robust to disturbances such as aperture clipping, and while there will be some effect on uniformity, it is less sensitive than other available shaping methods such as flat top shapers. This means one can work with larger beams and higher NA.

- spiral phase plates, like any phase plate, are thin, lightweight components that are easy to integrate into optical setups. Holo/Or’s vortex lenses are made of monolithic material (UV fused silica or ZnSe), with high LDT, making them suitable for high-powered applications, including those using multi-KW lasers.

Use of spiral phase plates in high power industrial laser processing

Due to their self-healing characteristic, beam profiles generated by a vortex phase plate tend to stay stable even when going through relatively narrow apertures that clip the edges of the beam. This makes such beam highly useful in various galvo-scanning applications, where often a gaussian spot results in uneven integrated intensity over the widths of a scanned line. Some known applications that benefit from the use of a spiral phase plate:

- Laser ablation for the removal of layers (passivation in solar panel backsides, for example). A phase plate is used to achieve a uniform scanned energy profile, similar too Holo/Or’s M-shaper concept.

- Laser cutting of thin foils, or dicing of thin semiconductor wafers. In such cases, it is important to have a uniform energy profile over the cross section, to reduce chipping and damage to the backside, and a spiral phase plate creates such a profile when the spot is scanned in a line.

- Laser multi-hole through drilling, where energy is better spent on the diameter of the hole instead of wasted in the center. This is often the case in PCB laser drilling using a galvo+ scanner setup. The vortex phase plate generates a profile that is maintained over the entire waist, even when that waist intersects an opaque material.

TL; DR - Q&A

What is a phase plate?

A phase plate is a thin, planer diffractive component that creates a pre-designed phase profile on laser beams going through it.

What can a phase plate do?

A phase plate can split incoming light, such as in the case of beam splitter phase shift plates, or it shape the light to pre-designed distributions such as higher modes or vortex modes.

What is a spiral phase plate? where is it used in high power laser processing?

A spiral phase plate is a special phase plate that creates a mode called a vortex mode, that when focused looks like a “donut” of light. This sort of donut is highly useful in laser ablation, dicing and drilling.