Introduction

A micro lens array (MLA) is an optical component used in many photonics based devices for various applications. The micro lens array, as suggested by its name, consists of an array of micron-scale lenses arranged and “packed“ together on a single supporting substrate.

Each of the micro lenses in the array is a plano-convex refractive lens, operating under the standard geometrical optics laws of physics, but when packed together, their cumulative effect can generate some more complex optical functions, interesting to use in various applications.

Micro lens array applications

Microlens arrays can generally be used in 2 manners or applications:

- Using each of the micro lenses as a single lens packed together on a single component – this option is often used for fiber coupling applications, medical aesthetics applications such as fractional treatments and various optical imaging applications.

- Using the entire array as a whole to generate a uniform illumination from a non-uniform input illumination profile. This method is often used in microscopy applications, medical devices, displays and cinema projection.

Micro lens arrays for spot array generation

MLA are often used to generate an array of focused spots with pitch equal to the array pitch, and spot size determined by the individual lenses NA. This method is especially useful when working at lower NA values and with shorter focusing distances, as for higher NA the micro lens aberrations often preclude diffraction limited performance. For most optical systems in this application group, a multi spot DOE with a focus lens can offer more flexibility and better performance.

Micro lens array as a homogenizer

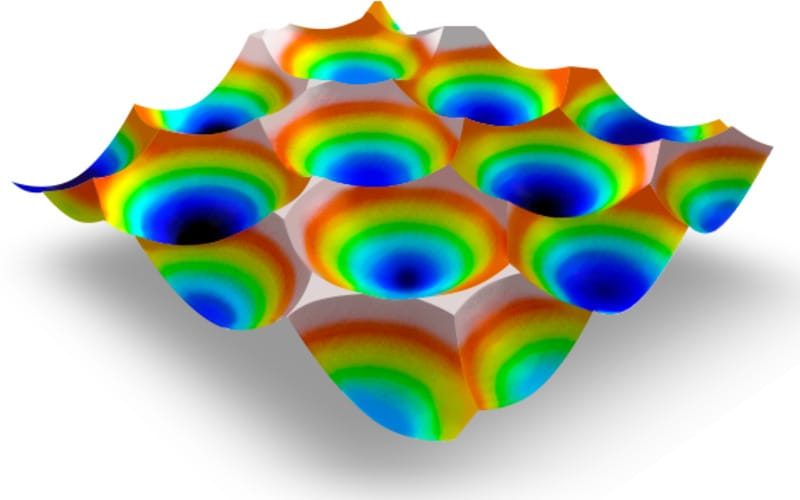

One of the optical functions micro lens arrays are well known for is homogenization of a light source. When the micro lenses NA are small enough (by design), the spots generated on the workplane by each of the lenses overlap each other, creating a more uniform and homogenized output spot than the initial source beam.

The generated spot also has flat-top intensity profile characteristics, as the energy sampled in each sub area of it is the integral of the energy in that specific area generated by all the spots that are generated by each single micro lens illuminating it.

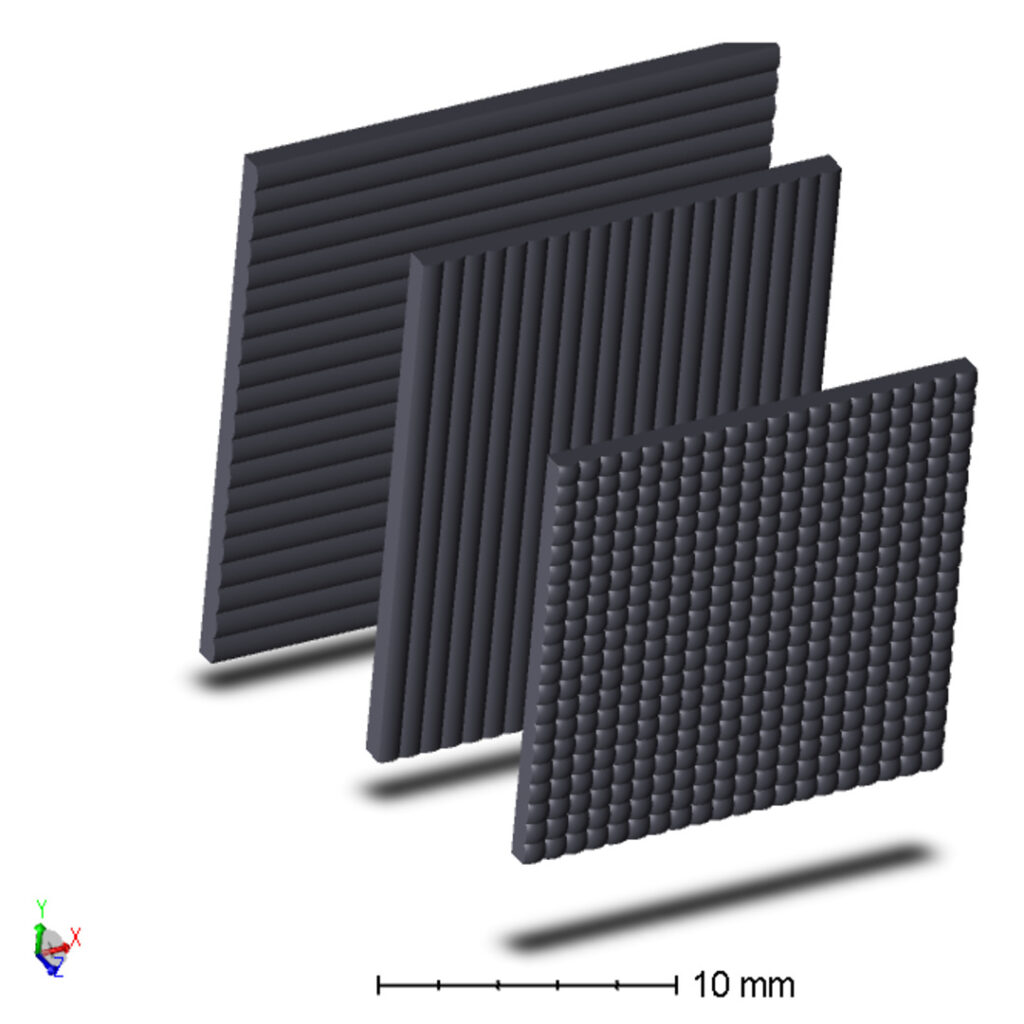

The homogenized, flat-top spot generated by the micro lens array can be shaped into various geometrical shapes depending on the arrangement of the micro lenses in the array. Possible shapes include line, round, square, rectangle and hexagonal.

Holo/Or offers a micro lens array with 100% “packing”, i.e. – covering the entire surface with no gaps between the lenses, to ensure maximum energy efficiency and optimal zero-order homogenization. We also offer broadband diffusers (BD), also known as engineered diffusers, which is a unique type of a micro lens array with a nonuniform arrangement, presenting much better shaping uniformity compared to a single lens array.

Fabrication of microlens arrays

Microlens arrays fabrication is not new to the world of optics and can be dated back to the 17th century with conventional grinding and polishing methods.

Fabrication processes have since evolved and become more accurate and precise, and with fewer and smaller production tolerances. Nowadays, micro lens array manufacturing methods range from diamond turning to grayscale lithography and etching, similarly to the process of integrated circuits and other microelectronics manufacturing.

At Holo/Or, microlens arrays, as well as broadband diffusers, are designed with computerized tools using in house proprietary algorithms and the design is later transferred onto the glass substrate using lithography and etching equipment.

The produced element can be used as a stand alone component in high-powered applications, or it can be used as a “master template” for replication by the various available replication methods and to a variety of substrates such as plastics or polymer on glass, depending on required volumes and power-regimes.

TL; DR - Q&A

What is a micro lens array?

A micro lens array consists of numerous lenses each with a diameter in the mm to um range, arranged and packed onto a single optical surface.

What are microlens arrays used for?

Microlens arrays are used in a variety of applications, typically for either imaging functions or for homogenization. Applications using microlens arrays include fiber coupling, microscopy, medical devices, displays, cinema projection and more.

Are microlens array a good beam shaping solution?

Microlens arrays can be used for beam shaping, however for optimal single component beam shaping and homogenization performance it is recommended to use broadband diffusers which are a subcategory of micro lens arrays, sometimes referred to as engineered diffusers.