Abstract

Background: Picosecond Laser Cutting of glass- Mechanism and requirements

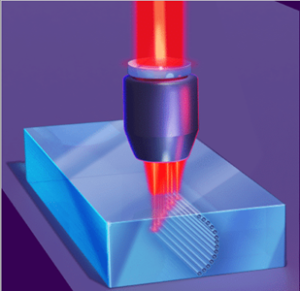

The demand for laser glass cutting is growing in many varied industries, from cellular phones and displays that tend to utilize specialized thin glass to shipbuilding and structural glass cutting, where thick glass components are required for greater strength. IR UPS lasers have become the preferred method of such laser glass cutting processes, enabling accurate cuts with a straight profile at high speed. The mechanism that enables picosecond laser glass is based on the non-linear absorption of the laser energy at very high energy density into a material that is normally transparent and has little absorption. The short pulse time creates extremely high, localized energy density inside the glass, leading to non-linear absorption, breakdown of the glass and a plasma filamentation effect. This plasma filament creates internal stress in the glass, at a very specific local area where the laser energy density is high enough. This stress then induces cleaving of the laser processed line with smooth, clean seam, often requiring the application of a post process thermal or mechanical stress. Due to the non-linear nature of picosecond laser cutting process and laser power constraints, the affected area cross section typically has a narrow diameter of 1-5um, while the depth of focus must cover the entire glass thickness. This can range from 0.2mm to 20mm, depending on the application, posing a major challenge to glass cutting in a single pass. Cutting with Gaussian beams requires multiple passes, since they cannot be focused to a tight enough spot while having a large depth of focus covering the entire glass thickness. This is due to the inherent limitations of the Rayleigh range, that are a basic principle in optics. Therefore, 3D beam shaping is required to achieve Bessel-like beams that have this extended focus range, or to split the focus into multiple foci spanning the glass thickness.Laser cutting techniques for picosecond laser glass cutting

Laser glass cutting technique can be divided into three main categories: straight cut, bevel/edge and combined cut.- Straight cut laser glass cutting is relatively simple- the cut is vertical to the surface of the glass, resulting in a straight cut with right angle corners. Such glass often needs to go through other post processing stages such as mechanical edge grinding to create a bevel for safety and durability reasons. Such cuts can be done by a single pass using by straightforward beam shaping such as Bessel beam generation. Holo/Or’s Modified Bessel beams generated by DeepCleave offer ideal distribution of the energy in the glass, enhancing single pass laser glass cutting for straight cuts.

- Bevel or edge laser glass cutting is more challenging, requiring a distribution of the laser energy in a diagonal line into the glass to create a bevel at the top or bottom of the glass. We at Holo/Or have developed 3D diffractive beam shaping optics capable of generating such lines of Foci at any desired angle, capable of such Bevel cutting. This type of laser glass cutting technique is challenging as the diagonal line needs to be at a precise position vs the side of the glass, and high NA optics with large enough field must be used to enable the line to stay at focus. Such optics are rarely off-the shelf, and often need to be developed on a case-by-case basis.

- Combined cut is the most challenging of the laser cutting techniques. In this case the laser should perform both the main cut and the top and bottom bevels simultaneously, in a single pass. This is typically done by advance 3D shaping of the beam into a line of spots or continuous line have a shape of a ‘C’ or trapeze.

Choosing the correct Beam shaping for different laser cutting technique

For the straight cut laser technique, Bessel beam generators such as DeepCleave and Diffractive axicons are a good shaping solution, as they increase the depth of focus along a line The modified Bessel beam generated by the DeepCleave has a flat top intensity profile along the cut, making it superior to the typical Bessel profile of axicon based solutions in terms of energy efficiency (thus, depth cut for a certain laser energy). For the other two laser glass cutting techniques, custom diffractive optics that combine a multifocal element and a multi-spot beam splitter are often the solution. Alternatively, freeform solutions can be devised to generate continuous lines in the glass at an angle. All such shaping solutions must matched with a tailored focusing optic with high enough NA and sufficient field to cover the entire cut line.Summary

Picosecond laser glass cutting usage is increasing in the industry, with many laser glass cutter machines developed for varied applications. Laser cutting techniques are constantly evolving, with correct beam often a basic requirement to achieve optimal cutting results. Different types of beam shaping solutions are suitable for different laser glass cutting techniques, for example DeepCleave and Diffractive axicons for straight cuts and 3D multifocal elements for curved cuts and beveling.TL; DR – Q&A SUMMARY

How do laser glass cutters use picosecond lasers to cut glass?

Ultrashort pulsed lasers create a nonlinear absorption that causes a plasma filamentation in the glass, generating regions of high internal stress that can be separated smoothly , resulting in a high quality, well defined cut in the glass.

What are the various laser cutting techniques for glass processing?

There are many different laser glass cutting techniques. The most common is straight cut, where the glass is cleaved vertically. More advanced laser glass cutting techniques employ slanted illumination to generate bevels or to generate both the main straight cut and the bevels at the top and bottom of the glass.

What diffractive beam shaping optics are suitable for which laser glass cutting techniques?

DeepCleave is useful for straight cuts, as it creates a flat top profile along the focus axis, resulting in higher speed cutting / thicker glass cutting at the same speed, with the same laser energy. 3D multifocal diffractive beam splitters are useful for bevel cuts and combined cuts, as they can generate any intensity distribution in the glass bulk.