What is coherent beam combining and why do we need it?

With the increasing demand for high-power, high-brightness laser beams in security applications such as missile interception and heavy industrial applications such as welding and cutting, the need for a multi-kilowatt solid-state laser solution becomes acute. However, the output power of a single fiber laser is limited by the nonlinear effects and thermal effects that occur at high power levels.

Coherent beam combining (CBC) is a technique that allows the output power of multiple lasers to be increased without compromising the beam quality, by using a beam combiner element . The beam combiner market is growing rapidly due to the ability to provide high-power laser beams with excellent beam quality. CBC has been used in various applications such as material processing, scientific research, and defense. In particular, Coherent beam combination has been widely used in security applications such as missile interception and heavy industrial applications such as welding and cutting.

How does Coherent beam combining work?

In coherent beam combining, several laser beams (typically from high power fiber lasers) with the same wavelength are combined to generate a high-power single beam, while maintaining their relative temporal phase. This can be done in many ways- for example, by starting with a master oscillator fiber laser, splitting it and amplifying the channels, then recombining the beams . Other method use a fiber laser array with a beam combiner element that collimates the outputs and corrects for deflection angles, creating a single combined beam.

The combined beam is the result of coherent addition, thus the process can have good combining efficiency giving high power laser output .

Why use diffractive beam shaping in CBC?

While this beam combining can be done using refractive optical elements such as mirrors, prisms, and lenses, these elements are bulky, heavy, and difficult to align. Furthermore ,refractive lens arrays tend to have tolerances on ROC of lenses and aberrations reducing the beam combining efficiency.

Diffractive optics are optical elements that use interference and diffraction to manipulate the phase and amplitude of light waves. Diffractive optics offer several advantages for CBC, such as high LDT, absolute angular accuracy, compact size (flat surfaces), and the ability to combine multiple optical functions into a single surface, reducing the amount of alignment needed in the system. They planarity means they add no aberrations , while the near absolute angular tolerances mean that ROC of diffractive lens in a lens array are all identical .

How do diffractive optical elements work?

Diffractive optical elements (DOEs) are transmissive phase elements that operate by creating a controlled retardation of the light wavefront that at far field is transformed into a desired intensity distribution. This controlled phase retardation is achieved by creating a micro relief structure on the face of the DOE, typically by using lithography-based methods to pattern and etch the surface. For complex, non-binary topographies, multiple binary production steps can be combined to generate a multi-level phase.

Some typical diffractive optical elements are diffractive beam splitters, that split the laser into multiple beams, diffractive lenses and prisms and diffractive beam shapers, that create top hat beam profiles of any desired shape at the focal plane of a lens.

How are DOEs used in coherent beam combining?

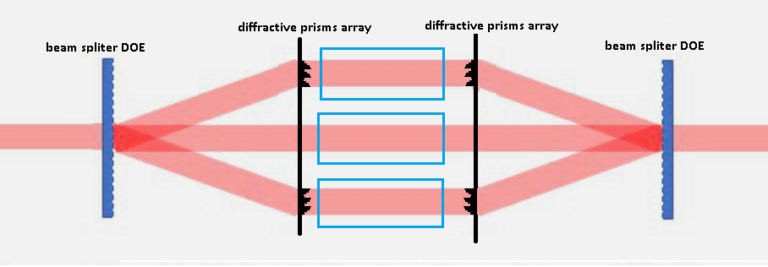

Diffractive beam splitters are used in CBC to split a single input beam into multiple output beams with equal or unequal intensities and phases. The input laser beam from the master oscillator is split into multiple channels using a prism or diffractive prism array. Each beam is then amplified separately before being recombined using another beam splitter.

In some cases, the amplifier cannot withstand the gaussian energy density of the input beam, with its high power at the center. In such cases, a beam shaper diffractive optical element can spread the energy to a flat top shape, enabling higher output power from the amplifier.

Another application of diffractive optics in Coherent beam combining is in phased laser arrays. In such cases, multiple in-phase emitters (such as high-power fibers) are combined by collimating them to be parallel to each other. In such applications, diffractive prism arrays can be used to introduce a controlled amounts of dispersion that compensates for the phase errors caused by the misalignment of the fiber channels. Diffractive lenses can be used to correct the wavefront errors by introducing a controlled amount of phase shift that compensates for the aberrations in the optical system. DOEs are especially useful in coherently combined ultrafast fiber laser systems, since they are thin windows that can be designed as reflective elements if needed, enabling minimal temporal dispersion.

The diffractive optics prism and lenses can be designed using computer-aided design tools that optimize their performance for specific CBC systems and can even be combined as a single DOE surface to reduce alignment sensitivity.

Summary:

Coherent beam combining (CBC) is a technique that allows the output power of multiple fiber lasers to be increased without compromising the beam quality. Diffractive optics are optical elements that use interference and diffraction to manipulate the phase and amplitude of light waves. Diffractive optics can offer several advantages for CBC, such as absolute angular accuracy, compact size, scalability, and integration of multiple optical functions in a single surface.

TL; DR - Q&A summary

1. How are diffractive beam splitters used in Coherent beam combining?

Diffractive beam splitters are used in CBC to split a single input beam into multiple output beams with equal or unequal intensities and phases. The input laser beam from the master oscillator is split into multiple channels using a prism or diffractive prism array. Each beam is then amplified separately before being recombined using another beam splitter.

2. How can diffractive prisms and lenses be used for coherent phased arrays?

diffractive prism arrays can be used to introduce a controlled amount of dispersion that compensates for the phase errors caused by the misalignment of the fiber channels. diffractive lens arrays can be used to correct the wavefront errors by introducing a controlled amount of phase shift that compensates for the aberrations in the optical system.

3. What are some other advantages of diffractive optics?

Diffractive optics can combine multiple optical functions in one surface, such as beam combining and lens or prism and lens. This reduces the alignment requirements on the CBC system.

4. How are diffractive optical elements produced? Are they good for very high power?

Diffractive optical elements are produced using lithography and plasma etching techniques, making them monolithic, high LDT components. They can withstand the multi-kW laser power levels reached in coherent beam combining.