Laser welding and other types of material processing are rapidly expanding applications that utilize the growing industry of high-power lasers. Together with laser beam shaping one can optimize the process for maximal throughput and process quality. However, high quality high power laser processing requires constant control and metrology to ensure process stability- in modern welding heads, the cost of optics and metrology systems can be of the order of half the laser cost!

Power meters and beam profiler cameras which are used to monitor laser beam characteristics often have lower LDT than the level of power used in the process, requiring some method of attenuation. For this application of high power laser monitoring and feedback, diffractive laser beam samplers are a highly suitable solution .

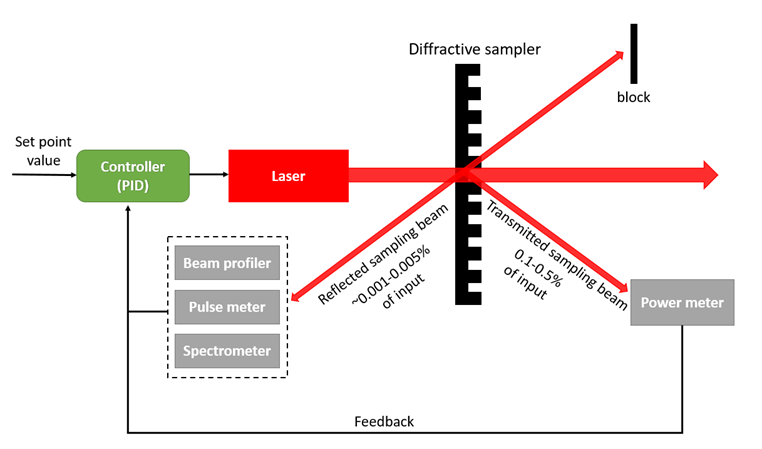

Diffractive beam samplers are thin, flat window that diffract a small, pre-defined fraction of the laser beam (0.15-1% typically) at a controlled angle. Most of the energy of the incident laser continues forward, unaffected, in the “zero order” while a small amount of the beam is diffracted into a higher order, providing a sampled beam for measurement of power with enough power to provide a stable reading when used with high power laser power-meters.

The diffractive beam sampler also has a back- reflected order which is typically attenuated by a factor of 1/100 relative to the sampled order, i.e a sampling of 0.001% of the input beam, enabling beam shape monitoring by beam profiler even for high power laser beams.

Since diffractive beam samplers are flat thin windows with high LDT, they are often used to monitor high power lasers where optical losses and wavefront distortions of the transmitted beam need to be kept to a minimum.

Why and where are laser beam samplers needed?

For multi kw lasers used in welding, it is often difficult to sample both main beam power and get a beam profile at the same time, as cameras often have much higher sensitivity (and lower LDT) compared to high-power power meters. This issue can be solved by using a single diffractive sampler. A diffractive laser beam sampler is a Diffractive Optical Element (DOE) designed to split a sub-beam identical to the main beam, with pre-determined small fraction of power, for example 0.2%. The main beam power can be sampled directly from the sample forward order with a power meter, while the reflected sampled order (which is attenuated by another factor of ~100 compared to the forward order) can be used with a

camera to monitor the beam profile. This enables real time control of both power stability and beam profile.

Advantages of diffractive laser beam samplers over other methods.

Diffractive laser beam samplers have many advantages over existing methods of power and beam profile monitoring. With some conventional methods, the laser beam is only measured at certain times, with others the beam is deflected at 90 degrees from the optical axis, and some methods rely on polarization of the laser beam. Here is a short list of the main advantages of diffractive laser beam samplers:

- Samplers are available for high-power lasers at a wide range of wavelengths.

With fused silica substrates for 0.193nm-3um and ZnSe for mid IR Co2 lasers, with LDT suitable for use with high-power lasers.

- Diffractive beam samplers are a single element solution, they do not require a module or large device, and are not sensitive to alignment or centration.

- Samplers do not shift of tilt the main laser beam used for the process; they leave it completely undisturbed and do not add aberrations to the wavefront.

- Diffractive samplers are not sensitive to and do not change the polarization of the laser beam.

- Samplers can be made with large aperture optics for use with large input laser beams.

Ultra-low back-reflected sampling ratios of down to 0.001% of the input beam allow use without additional filters and attenuators.

TL; DR – Q&A SUMMARY

What is the use of a diffractive laser beam samplers?

Diffractive laser beam samplers are used for multi kW laser systems where power and beam characteristics need to be measured in real time.

How do diffractive lasers beam samplers work?

Diffractive laser beam samplers are specifically designed diffractive gratings that create a smaller beam, identical to the main beam, with a fraction of its power. This beam can be used with power-meters to maintain laser stability. Laser beam Samplers also create a back-reflected beam with an even smaller fraction of energy that can be used with beam profilers, spectrometers, cameras etc.

What are the advantages of diffractive laser beam samplers?

Diffractive laser beam samplers hold all the advantages Diffractive Optical Elements, with distinct advantages compared to other available laser beam samplers. Main advantages are use of a single elements instead of a device or module, availability in a wide range of wavelengths and no effect on main and sampled beam profile. Diffractive laser beam samplers can also reach ultra-low sampling ratio of ~0.1% in forward order for use with power-meters and even ~0.001% in back-diffracted order for use with sensitive measuring devices.