Choosing the correct Focusing optics is critical in many multi focal and elongated focus applications such as glass cutting. This selection guide helps you evaluate the right lens to use with our DOEs.

Case study: Aspherical lenses as the focusing optics for axial shaping in high power, Ultra Short Pulsed Laser Applications

Overview

The purpose of this case study is to help in the task of finding the right focusing optics for industrial applications using USP lasers with focus shaping effects such as Bessel-like beams and multiple foci DOEs. We give practical tips, review a few catalogue lenses specs and analyze the performance of a multifocal diffractive lens with various aspherical lenses , using ZEMAX Optical Studio.

Holo/Or

This case study was composed by Holo/Or LTD. Holo/Or provides a vary of axial shaping solutions such as Diffractive Multifocal lenses, Diffractive Axicons, and our all in one solution the DeepCleave module for laser glass cutting. We would like to support our customer who intend to use focal element and help you choose the right focus optics for high NA cases.

Main section

Focal shaping includes two types of solutions:

- Continuous shaping – Diffractive Axicon for Bessel beam generation.

- Discrete splitting- multifocal diffractive elements (online Calculator).

Typical applications:

- Glass cutting

- Glass bulk modification

Most of these applications require high power densities and therefore tight focusing to small spots (1-5um typically). Thus, Aspheric lenses emerge as a good option for on-axis focusing.

Advantages of aspherical lenses:

- High NA

- large Clear Aperture

- large working distance

- cost effective.

- high power ready

- available design files

Quality parameters for axial beam shaping are spot size (central lobe size for Bessel like beam) for all foci or whole DOF range.

A few words about focusing objectives:

The data most suppliers provide for objectives is not informative about the performance for high power USP laser applications. Design files are rarely available, thus it is hard to say if objectives will perform as needed with USP lasers in focal shaping applications.

A remark about NA:

There is a difference between lens (objective) NA and beam NA. For laser applications NA is defined by beam size and it will always be smaller than NA of the optics. The rule of thumb is that maximum beam NA for diffraction limited performance and aperture minimum clipping is NA optics/1.5. For example, Aspherical lens with NA 0.5 and Clear Aperture 22.5 mm can be used with maximum beam size 15 mm and equivalent beam NA is 0.3.

Aspherical lens categories- general selection guide

There are many types of aspherical lenses dedicated to different uses, and it’s easy to get lost in such a large variety.

The filters in products page should be limited to

- Glasses: *N-BK7(Crown glass), Fused Silica (any of the different grades and brands).

- Coating: V-coating to specific wavelength

- Design wavelength: laser wavelength or closest available

*N-BK7 lenses will typically be lower cost compared to Fused Silica lenses with the same surface precision. Lenses made of N-BK7 can be a good and cost-effective option for many industrial applications.

After filtering the above categories, the choice will be limited to just a few options if any.

If there are no options for specific EFL, consider other lenses with same the NA. Larger aspherical lenses have advantage of longer BFL, and easier alignment.

More parameters to consider:

- Recommended RMSi for aspherical surface < 100 nm

- Flatness for flat surface lambda/4 @633nm

Note: Since an Aspherical lens is a single element that does the entire optical “work”, and has high NA, it is very sensitive to all tolerances including lens geometry and mechanical alignment.

There are many other parameters that appear in lens specs. It’s not really possible to know what lens quality will be good enough for your application, except by testing it in process. The rule of thumb is to choose as high end as possible.

Performance analysis of stock Aspheric lenses from Edmunds Optics and Sill Optics

The basic check will include focusing quality of the lenses in operation wavelength. If the lens does not perform well for simple focusing it will not be good for the more challenging task of axial shaping along the focus axis.

For comparison we took 4 lenses with similar EFLs and modeled with same NAs of 0.3. The first one is an Aspherical lens model 33-019 with design wavelength 1064 nm, the second lens is Aspherical lens 49-593 with design wavelength 587.6 nm, the third lens is Best Form Aspherical lens 89-439 with design wavelength 1064 nm and it has second surface of convex type, and the last lens is Best Fit Aspherical lens from Sill Optics model S1ADX0220-328 with design wavelength 1064nm.

After opening ZEMAX files it found that lenses 33-019 and 49-593 are same lens except of coating type. Lens 49-593 was removed from the comparison list. Improper, misleading, or unclear specs are also part of dealing with finding the right lenses. Sometimes the spec table is not up to date, so ask the supplier to provide the necessary information.

Here is a short summary of the examined lenses:

Shape | Convex-Plano | Plano-Convex | Bi-Convex |

Material | Fused Silica | N-BK7 | Fused Silica |

Description (By Supplier) | “… Aspheric Lenses are designed to maximize performance in high power Nd:YAG laser applications …” | “…Best Form Aspheric Lenses produce diffraction-limited spot sizes at the design wavelength, which is ideal for focusing or collimating applications…” | “… Aspheres offer the great advantage to accomplish monochromatic imaging tasks with one optical ele-

ment …” |

Lens layouts. Collimated light incident on lens from the left side. |  |  |  |

Let’s check out how they perform.

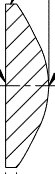

Our comparison starts from focused spot analysis. For analysis it is recommended to use physical optics methods such as Huygens PSF.

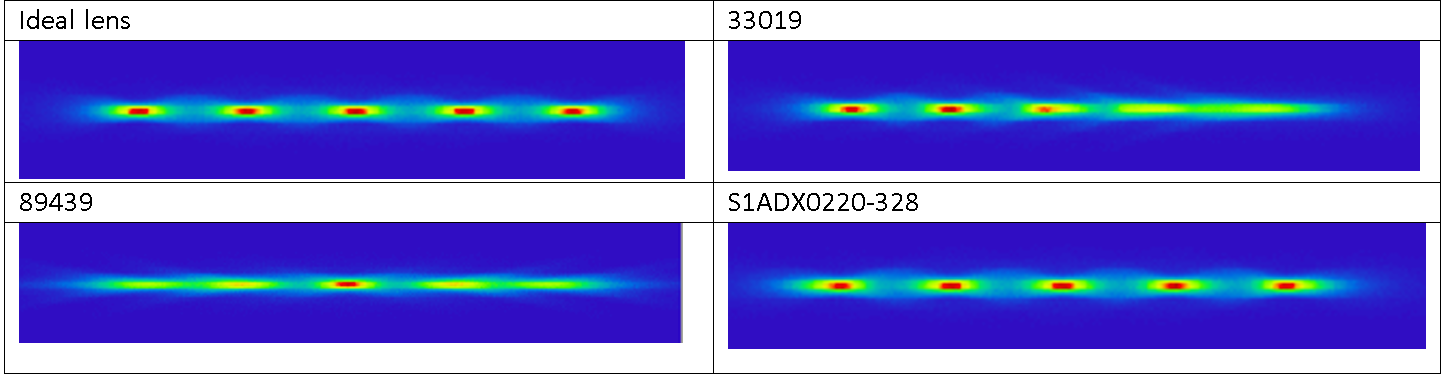

In the following figure we show the spots profile of a focused spot at NA 0.3. Lenses 33-019 and S1ADX0220-328 show the same diffraction limited focal performance, while the 89-439 has a slightly larger spot. In the next section we will continue our investigation on a specific case study.

The case study

Laser parameters:

- Wavelength 1064 nm, M^2 1.1, beam size 15 mm for EFL 25 mm and 12 for EFL 20 mm (same NA).

Design task:

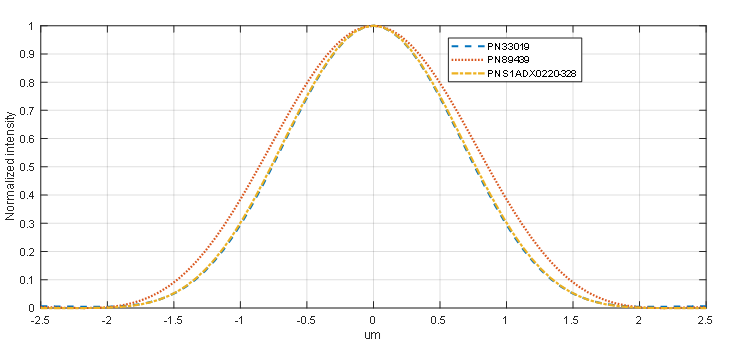

- System 2: 5 foci with full distance of 100 um and focal spot diameter < 2.5 um

Design calculations:

Required input beam size 15 mm (EFL 25 mm) and 12 mm (EFL 20 mm) to reach spot < 2.5 um. Calculated by HOLO/OR’s Diffraction limit calculator.

We designed a setup of a multi focal DOE+ ideal lens in ZEMAX using HOLO/OR’s tutorial, and then replaced the ideal lens by an Aspherical lens.

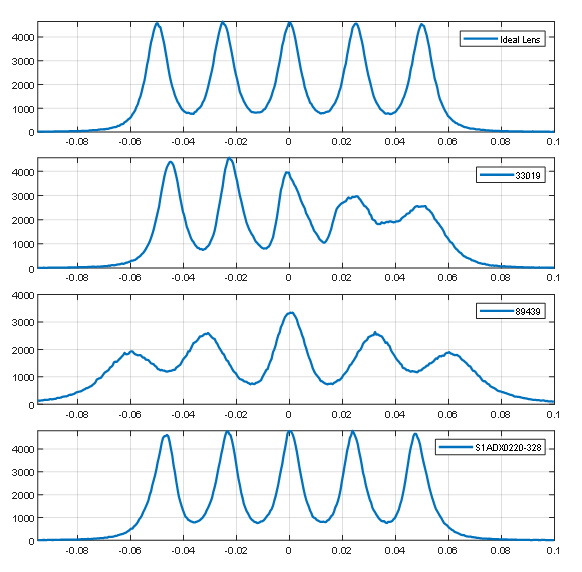

Intensity profile along Z axis for the reviewed lenses:

ZX plane intensity distribution

The performance was evaluated under the same optical conditions, using Geometrical Image Analysis method and scattering effect to show realistic Gaussian beam behavior. The profiles clearly show that for lens 33019 beam quality for foci positioned closer than the original focal plane is better than foci after it. Lens 89439 has less preferred performance compared to the other tested lenses. It has good central focused spots, but other spots are aberrated. The last lens in the test S1ADX0220-328 has almost perfect performance compared to the ideal lens.

Summary and conclusions

Aspherical lenses have the right set of parameters to be used for axial laser shaping such as multifocal and Bessel beam applications.

All presented lenses passed the simulation test. It’s clear that we have a winner, but not by a big gap from other participants. We think that bi-convex configuration Aspherical lens from Sill was a significant advantage in this case study.

Bessel beam behaves similarly as multifocal beam and shows same conclusions.

ZEMAX OpticStudio is a powerful tool for analysis of Z (axial) shaping applications.

Aspherical lenses are still new and less familiar in the optical element’s family. Lenses with same EFL, NA, and material can vary even in nominal performance when we are talking about positions different than the focal point. The lenses specifications include many parameters that are not highly useful in understanding if they are suitable for the application purpose or not- a simulation evaluation is recommended.

Extra reading:

https://holoor.co.il/application/laser-glass-cutting/ laser glass cutting application note.

https://holoor.co.il/application/diffractive-multifocal-bifocal-trifocal-application-notes/ multifocal lenses application note .

https://holoor.co.il/application/diffractive-elongated-focus/ elongated focus application note.

Technical papers:

https://holoor.co.il/optical-calculator/multifocal-lenses/ online calculator for multifocal lenses

https://holoor.co.il/method-for-laser-source-definition-in-zemax/ Laser Source Definition in ZEMAX To Enable Realistic Modelling With Raytracing

https://holoor.co.il/wp-content/uploads/2017/11/Multifocal_Tutorial_Zemax.pdf design of Diffractive Multifocal lens with ZEMAX