A DOE, diffractive optical element, sometimes referred to as diffractive optical lens, is an optical device used in laser systems to alter the phase of the light passing through it, in a manner that affects the light’s intensity profile and distribution. The generated illumination profile going out of the diffractive optical lens (the light’s shape and angular intensity) will have different characteristics than those of the input beam, as determined by the optical function of the diffractive optical element design.

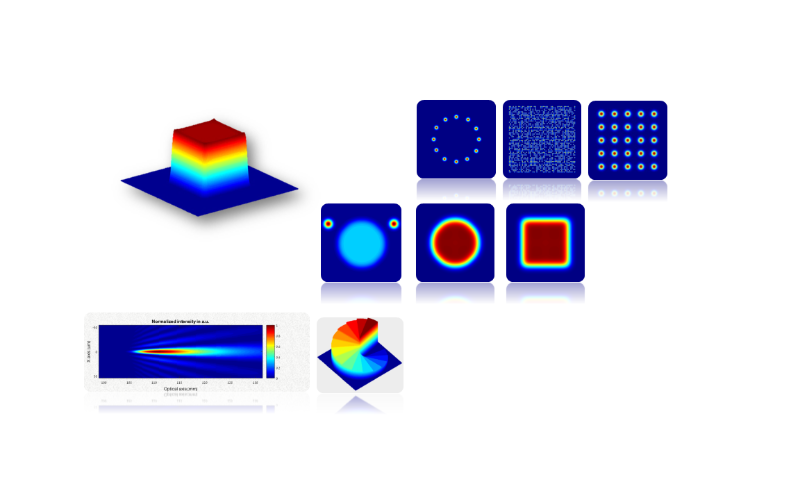

The optical functions achievable with diffractive optical elements can be divided into 3 main categories, that refer to the output of the DOE:

Generally, all DOEs can be customized and, in many cases, multiple optical functions can be designed to be generated together by a single diffractive surface

The increasing availability of laser power, along with the continuing reduction in laser price-per-Watt, enables a wide variety of applications now having redundancy in power density, to split the beam to increase throughput or shape it to improve accuracy, increase treatment or sample area, or otherwise improve system’s performances. Some of these applications include industrial macro and micromachining processes, glass cutting, aesthetic treatments and medical procedures, sensing and vision applications, metrology, microscopy and other scientific applications and many more.

Diffractive optical elements are fabricated from optical windows, meaning they are flat, small and lightweight, which makes them a useful go-to solution where compactness is of the essence. They offer complex optical functions with flexible properties, which otherwise requires highly complex and expensive optical setups, and sometimes are completely not achievable in any other method. Read our extensive guide to the advantages of DOEs for different use cases

A DOE is an optical device used in laser systems to alter the phase of the light projected through it, in a manner that affects the projected light’s intensity profile and distribution

DOEs offer 3 main optical functions, some of which can be convoluted together: beam splitting, spatial beam shaping and focal beam shaping.

Amongst laser applications utilizing DOE are industrial macro and micromachining, glass cutting, aesthetic treatments, metrology, microscopy and more.

DOE are flat, small and lightweight optical components offering complex optical functions with flexible properties, otherwise either requiring highly complex and expensive optical setups, or are completely not achievable in any other method.

Design and Manufacture of Diffractive Optical Elements for high power lasers

DESIGN & MANUFACTURE OF DIFFRACTIVE OPTICAL ELEMENTS

Want to discuss your project with us?

Leave your details and

we’ll reach out shortly!