Top Hat Diffractive Optical Elements (DOEs), also known as Flat-top, are beam shaping optical components that generate a uniform energy distribution at desired shape with sharp edges. This article reviews their principle of operation and the use of Top-Hat DOEs in LED UV Laser Lift-Off applications.

Background: Laser lift off of Micro LED

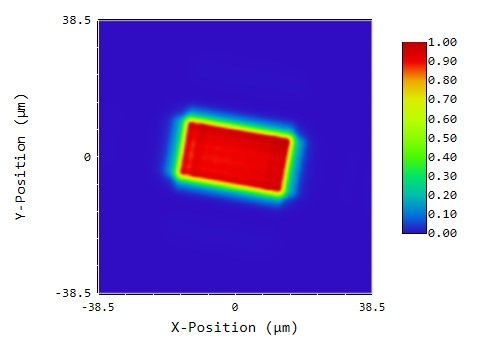

GaN based Micro LED have advantages over standard LED in efficiency, brightness, pixel density and operation envelope. These LED are tiny (30X20um) structures often grown on sapphire substrates, from whom they must be separated to bond them to the active layer of a display. This separation is of achieved with Laser lift off, using UV wavelengths. The laser energy is absorbed in the interface between the GaN and sapphire, weakening the bond and enabling separation with almost no mechanical force.

In recent years, we at Holo/Or have seen increasing interest in utilizing an accurate top hat beam shaper to process the exact Micro LED shape, with scanning to achieve area processing. For this purpose, diffractive Gaussian to top hat beam shapers are the preferred means, as they achieve unparallel shaping accuracy, uniformity and edge steepness, even for very small shapes.

How Does Top Hat shaper work?

A top hat shaper is designed to generate a uniform energy distribution, by creating a top hat laser beam at the focus of the system lens. These Analytical Top Hat beam shapers are suitable for coherent, single mode input, and are usually designed for a TEM00 Gaussian input beam with M2<1.3 . They work by a smooth change of the phase front, with no overlapping any section of the beam, creating a smooth, speckle-less Flat-Top intensity profile, with very high conversion efficiency. To achieve optimal shaping, these Top Hat shapers require a well-defined input beam diameter, good centering accuracy and laser-grade, aberration free focusing and relay optics with a clear aperture of at least X2 input beam diameter.

Challenges of integrating Top Hat beam shapers in Micro LED UV liftoff

MicroLED liftoff possess several unique challenges for gaussian to top hat beam shapers.

- The short wavelength uses (355nm, 266nm) limit the selection of F-theta suitable for this application.

- The desired shapes are often very small (35X20um rectangle with a top hat energy profile is ), while edge sharpness of 3-4um is often required

- To achieve such edge sharpness, a small diffraction limited spot is needed, thus a high NA in the F-theta

- Such high NA F-theta often have small scan field, that are even more limited due to the fact that one must use a beam the is X0.5 or less than the maximum beam defined for the F-theta, to avoid strong deformation of the Top-Hat.

How does Holo/Or meet these Challenges?

- Holo/Or offer beam shapers at all wavelengths, including deep UV to Uv (193nm-405nm). This enables easy integration of our elements in UV scanning systems for laser lift off, made simpler by the fact that our elements optimal flat top is achieved at the focal plane of the scan lens (i.e they create no focal shift).

- To handle the sharp edge requirements, Holo/Or has developed the Stable Top Hat top hat shapers family, that has sharper transfer region.

- By working with our strategic partners , ScanLab, we can together offer stage integrated scan systems such as XLscan that enlarge the scan field far beyond the field of the F-theta.

How to integrate our diffractive Top Hat laser beam shaper into your UV scanning system?

Holo/Or has an extensive installation guide and application notes, aimed at facilitating diffractive Top Hat use. All Top Hat types are sensitive to tolerances, and require careful work and pre-alignment. The main requirements in Top Hat applications are:

- Single wavelength, tolerance ±2%

- Single mode TEM00 laser with M2<1.3

- Beam diameter as designed, tolerance ±10%

- Accurate focus – defocus tolerance in Z is approximately the Top Hat size in the focal plane.

- Clear aperture at least X2 input beam diameter, for all optics from the DOE top hat shaper to the focal plane.

TL;DR - Q&A summary

What is a Micro LED UV laser lift off?

Micro LED UV laser lift off is a process used to separate MIcroLED from the sapphire substrates they were grown on, using high power UV lasers.

Why are Flat Top beam shapers used in MicroLEd laser lift off?

A flat top beam shaper can create the exact rectangle shape to cover only the microLEd itself, without wasting energy or damaging nearby units. Holo/Or's diffractive Top Hat shapers are perfect for such applications.

What are the challenges in this Top Hat application ?

The main challenges are the short wavelength used, the high NA required, the fact that a large clear aperture is needed to avoid distortion of the top hat shape, and the required small rectangle shape with sharp edges.

How do Holo/Or flat top beam shapers handle the challenges in this Top Hat application?

Our Stable Top hat shapers provide the sharpest edge of all top hat beam shapers in the market, reaching half a diffraction limit. Our thin, high power compatible pure UV fused silica elements are easily integrated in scanner+F-theta setups with high NA, and by working with our partners Scanlab, we can offer a solution for large scan fields.