Review laser damage threshold (LDT) test results of our DOEs

LDT Certification from standard lab tests

Introduction

With ever-increasing laser power, many system integrators and users are concerned, that their optical elements may not withstand the high-power incident on Thus, the parameter of laser induced damage threshold (LIDT or LDT), becomes an important figure when choosing optical elements for laser systems.

Lasers operate in a wide spectrum of wavelengths (from ultraviolet to far IR) and temporal regimes (ultrafast to continuous wave). Different temporal regimes face different damage types as described in the below table:

| Ultra-short pulse (t < 0.5[ns]) | Nano-second pulse (0.5[ns] < t < 100[ns]) | Continues Wave (CW) (t > 1[μs]) | |

| Damage type | • Dielectric break-down • Avalanche Ionization | • Dielectric Breakdown • For high pulse repetition rate, thermal effects may occur, similar to those for CW beams. | Material is overheated, which causes chemical degradation |

In the real world (outside optical design tools using ideal lenses), there are three main fields that affect the LDT of an element:

- Fabrication –

- defects in the raw material and manufacturing.

- Holo/Or’s solution – Our standard raw materials have high optical quality (i.e., we mainly use Fused-Silica with 20-10 Scratch-Dig or better). Our fabrication procedure is done in a clean room, and every element is measured and inspected for defects.

- Coating –

- contaminants trapped in the AR thin film.

- Holo/Or’s solution – We mainly use Ion-assisted-deposition (IAD) anti reflection (AR) coating with high QA.

- Use –

- Thermal recovery period, environment in which the element is used, and how it is cleaned / protected.

- Holo/Or’s solution – Although this side of the equation depends on the user of our optical elements, we have prepared protocols for safe use and cleaning, as well as thorough LDT tests (see example below).

Laser damage threshold tests of Holo/Or's DOEs

The described below tests were takes as part of LASHARE EU project (courtesy of BOSCH).

Experiment:

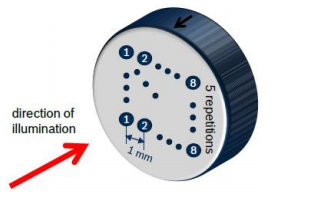

Illumination of 8 positions with increasing power, in a production environment (not a clean room).

Test procedure:

- Wavelength – 1030[nm]

- Repetition rate – 800[kHz]

- Pulse duration – 6[ps]

- Spatial pulse shape – Gaussian

- Temporal pulse shape – Gaussian

- Duration of illumination – 30[s]

- Subsequent illumination of positions P – 1, …, 8

- Pause between positions – 5[s]

- Distance between spots ~ 1[mm]

- Spot diameter on surface – 70[um]

- Repetitions of experiments – 5

TEST RESULTS:

No visible damage (p1,…)

Tested components:

- Material: UV Fused silica

- Surface Quality: 20-10 Scratch-Dig (or better)

- Coating Performance: Ravg < 2%

- Diffractive grating:

- Uncoated

- Non-diffractive side coated

- Both sides coated

Damage (pXX,…)

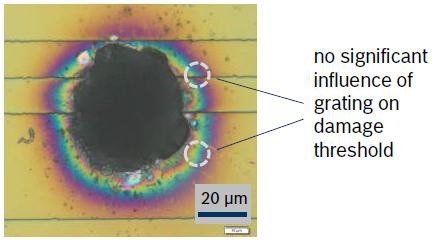

- The same damage occurs on a plain area as well as an area with grating

Uncoated | Non-diffractive side coated | Both sides coated | ||||

Undamaged | damage | Undamaged | damage | Undamaged | damage | |

Power (average) [W] | 57 | 58 | 62 | 64 | 53 | 54 |

Fluence (average) [J/cm2] | 1.95 | 1.98 | 2.12 | 2.18 | 1.81 | 1.84 |

Intensity (peak) [GW/cm2] | 308 | 313 | 335 | 344 | 285 | 290 |

- The undamaged column represents the highest value measured without detecting any damage on element. Thus, the damage column represents the lowest power value showing damage to element.

Conclusions:

- No significant influence of diffractive grating on damage threshold compare to a regular surface. The DOE will withstand the same LDT as a regular lens made from the same material (FS, ZnSe, Plastic….)

- If other optical elements are used in the system, diffractive element with the same material (glass or plastic) can be safely used.

- LDT is similar for uncoated, double side coated, and single (non-diffractive) side coated. i.e our AR coating has negligible effect on the DOE.

- It is recommended to operate below 50% of the LIDT. Since, depending on material, wavelength, rep. rate, environmental properties, coating type and other factors LIDT may change in time.

- The data presented is based on measurements in a professional lab. Still the data may vary a bit by type of design and therefore the numbers mentioned are not a full guaranty of this LDT, but more a reliable reference.

Test results from customers*:

* Holo/Or is not responsible for results from customers

- LDT for CW > 6 [kW] @ 10600[nm], ZnSe.

- LDT > 6[J/cm2] @ 1064[nm], 7[ns] pulse, no AR coating, Fused-Silica. LDT < 2.1[J/cm2] @ 532[nm], 7[ns] pulse, AR/AR coating, Fused-Silica.

Scaling of test data for pulsed laser

When scaling data obtained from real test results, on should remember, that this will only be a good estimation.

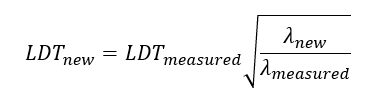

- Wavelength – Damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 [J/cm2] at 1064 [nm] scales to 0.7 [J/cm2] at 532 [nm]):

- Beam diameter – large beam sizes are more likely to illuminate a larger number of defects, which can lead to greater variances in the LDT. For beams sizes greater than 5 [mm], the LDT [J/cm2] will not scale independently of beam diameter due to the larger size beam exposing more defects.

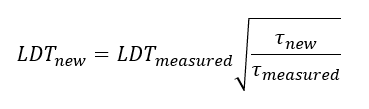

- Pulse length (τ) – The longer the pulse duration, the more energy the optic can handle. For pulse widths between 0.5 – 100 [ns], damage threshold has an inverse square root relationship with pulse length such that as you move to shorter pulses, the damage threshold decreases.

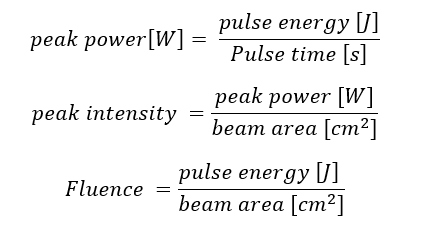

- Useful formulas:

LDT in plastic elements

Similar to glass materials, several parameters influence the results:

- Power density

- Dust (absorbs energy)

- Heat conduction (dependent on mounting).

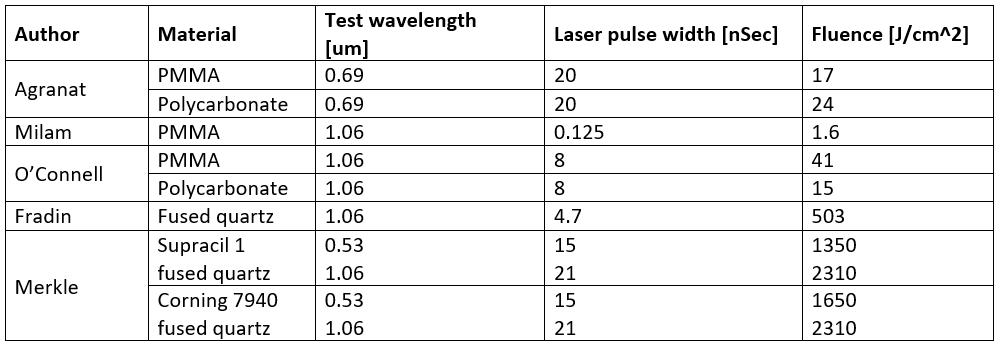

The table below shows measured single-pulsed threshold peak fluences for bulk laser damage in several polymers & glasses:

It is easily shown that optical glass has 10-50 times greater LDT than polymers.

References

- Thorlabs, Laser Induced Damage Threshold Tutorial: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=9025&tabname=Damage%20Thresholds

- High Laser-Induced-Damage Threshold Optics: http://www.photonics.com/Article.aspx?AID=46171

- Lasers in Polymer Science and Technology, Volume 3, by Jan F. Rabek, Jean-Pierre Fouassier, P.105-106

Subscribe to our newsletter

Fill in the form below and stay updated with the newest technologies, industry applications and upcoming events.