In recent years, there is a clear trend of increasingly using random dot pattern generators for 3D sensing measurements applications that utilize structured light methods.

Structured light is one of two main methods for 3D depth sensing, the other being Time of Flight. In structured light, a predefined pattern created by a diffractive beam splitter is projected on a scene or a surface creating an image with depth-dependent deformations in the known pattern. This image is captured by a sensor, and an image processing algorithm recognizes the deformations in the known pattern to calculate the depth of each of the spots and create a digital 3D map of the objects in the scene with depth data on each of the spots.

In many cases, customers prefer using a random or pseudo-random dot pattern, instead of a dot array or grid, as the random pattern enables position encoding for the image processing algorithm.

A random dot generator is the projector module of a 3D depth sensing camera or system. It consists the laser source (typically in the NIR spectrum with a wavelength of either 850nm for indoor applications or 940nm for outdoor applications), a collimator lens and a diffractive beam splitter. The diffractive beam splitter in the assembly is in fact, the random dot pattern generator.

There are 2 approaches to generating a random dot pattern with a diffractive optical element:

· Approach A: Using a single emitter laser source with a random dot pattern generator being the diffractive optical element (DOE). In this approach, the DOE is designed to split the input beam into any desired number of orders in a random or pseudo-random arrangement (typically for 3D sensing this is thousands of spots).

· Approach B: using a pseudo-random array of laser emitters (VCSEL sources are commonly used in this approach), and duplicating the array using a diffractive beam splitter with an arranged matrix of orders. Each of the beam splitter orders is in fact a duplication of the original array or “tile”, similar to it in each spot characteristics, with the energy equally divided between all spots, creating a semi random dot pattern all over the field of view.

One of the main concerns for using a diffractive beam splitter as a random dot generator, is creating the exact right pattern to avoid gaps or overlaps. In approach B, incorrect design may lead to gaps between the duplicated “tiles” creating gaps with no energy in between them, or alternatively overlaps between the “tiles” creating areas with indistinct spots.

To avoid these gaps or overlaps, Holo/Or has developed a unique design algorithm enabling us to perfectly stitch the tiles to create a continuous pseudo-random dot pattern from a well collimated source, used to design our structured light DOEs.

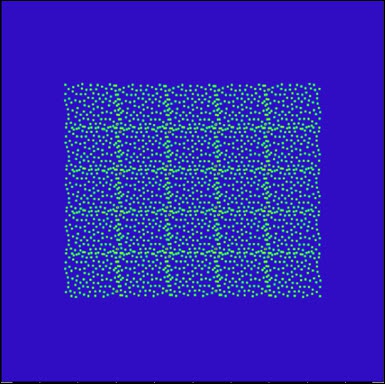

Incorrect VCSEL stitching of random dot pattern with overlaps

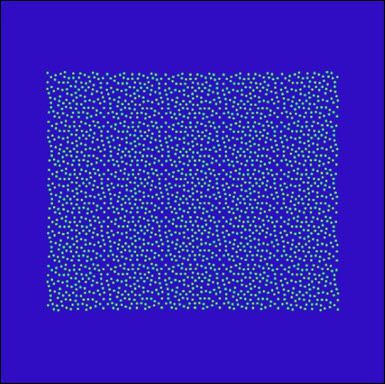

Correct VCSEL stitching of random dot pattern

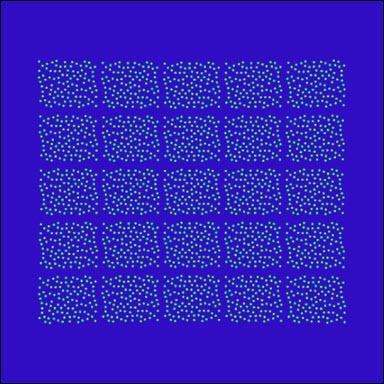

Incorrect VCSEL stitching of random dot pattern with gaps

If the source is uncollimated and highly divergent, as in many of the cases especially with VCSEL sources, we offer a customized diffractive collimator designed specifically to the source pseudo-random pattern arrangement and the diffractive beam splitter, resulting in a perfect dot pattern over the entire field of view.

Typical applications of random dot generators used for structured light 3D depth measurements include:

And many more.

Diffractive beam splitters have a few distinct advantages in comparison with alternatives, making it the superior solution for structured light 3D sensing applications:

A: a random dot generator is a diffractive beam splitter designed to create a random or pseudo-random dot pattern when light is propagated through it.

A: a random dot generator is used in combination with a collimated laser source or a VCSEL source to create a 3D image of the area the light is projected on for structured light cameras.

A: when using a VCSEL source for structured light imaging projection, one can duplicate the VCSEL emitter arrangement to create a pseudo-random dot pattern using a diffractive beam splitter.

Design and Manufacture of Diffractive Optical Elements for high power lasers

DESIGN & MANUFACTURE OF DIFFRACTIVE OPTICAL ELEMENTS

Want to discuss your project with us?

Leave your details and

we’ll reach out shortly!