M2 Transformation Module

HOLO/OR’s M2 transformation module is a part of our full LeanLine solution, that we offer as a stand-alone solution for customers interested in doing their own line shaping. This module is a cost-effective solution to get almost-single mode (SM) beam quality in one axis, using a multi-mode (MM) laser as the input.

It is extremely easy to align, maintains the same optical axis, and has low NA optics; making it easy to integrate with existing line focusing optics. Unlike with competing solutions, the input beam can be round, and is not required to be elliptical in shape. Just insert the module into your beam path, and after some fine adjustment you will have an M2 transformed beam.

Diffractive solution advantages:

- Internally developed based on HOLO/OR’s unique IP.

- Easy alignment and installation – the module comes pre-aligned and sealed.

- Extremely high precision for beam quality transformation, achieved by the lithography production process.

- A fully transmissive (no reflection), on-axis system.

- Aberration free.

- No internal focus points.

- Available in a wide spectral range from DUV 193nm to 1940nm NIR.

- Made of high-quality UV fused silica with high power AR coating on all surfaces.

Specifications:

* One wavelength per system, max spectral width 2% of input wavelength.

Principle Of Operation

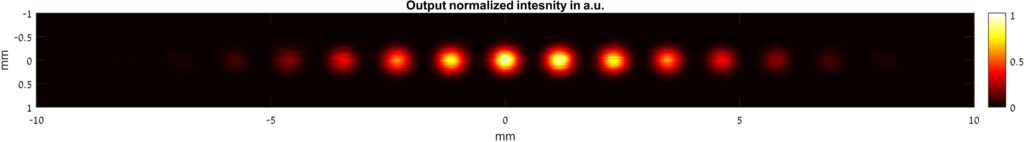

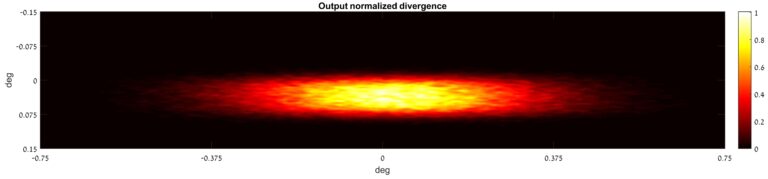

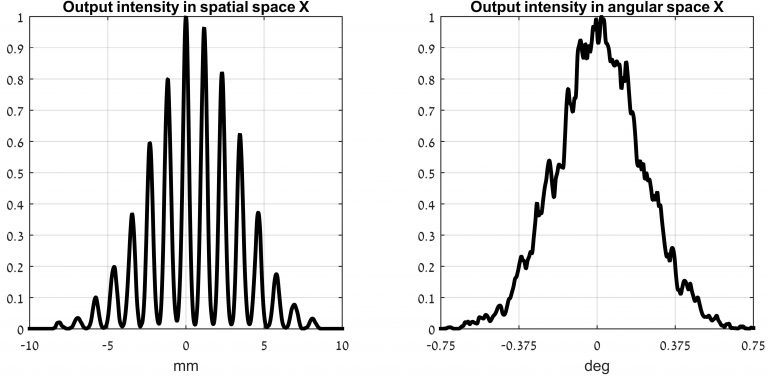

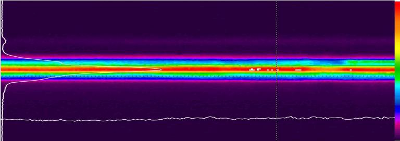

The output shape consists of sections separated by equal distances with near SM quality in one axis (fast axis) and highly MM in the second axis (slow axis). These separated low M2 sections can be reshaped and focused to a thin, diffraction limited line with good homogeneity; suitable for the application needs of material processing.

M2 Transformation Module Simulations

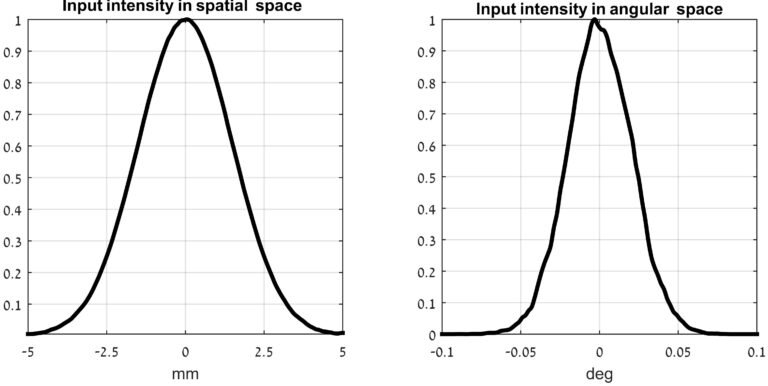

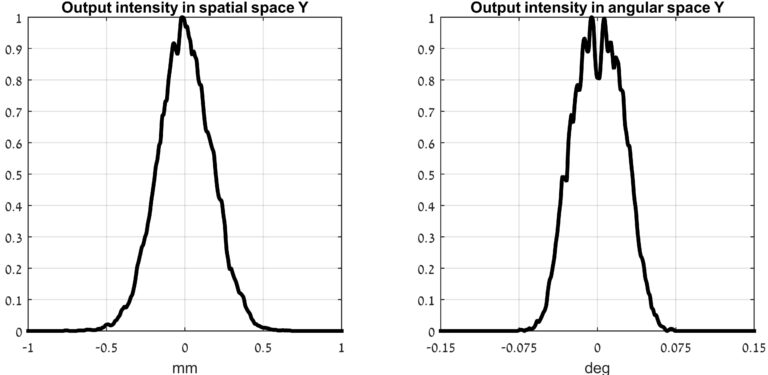

Below are simulated performance results of the M2 transformation module. The upper two profiles show intensity and divergence of the round multi-mode laser source with wavelength 343 nm, beam dia. 6 mm, and divergence 0.083 deg. By using our M2 calculator, those calculated beam parameters are equivalent to an M2 of 20.

The lower pictures demonstrate intensity and divergence at the M2 transformation module exit. In the axis with small M2, the beam has a size of 0.65 mm, and divergence 0.094 degrees. The calculated M2 is 2.4.

LeanLine(TM)

LeanLineTM is HOLO/OR’s innovative solution for transformation of a round input beam into a narrow laser line, useful in various high-power applications, especially with UV and green wavelengths (343, 355, and 532 nm).

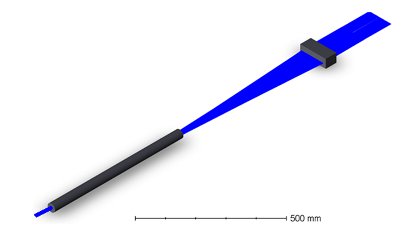

HOLO/OR offers a robust 2-module system that converts a low coherence, round input into a narrow line with a user determined length (100mm-750mm).

Our solution is based on proprietary diffractive beam shaping concepts and can be tailored to any wavelength from 193nm deep UV to 1940 nm IR lasers.

By utilizing this solution, you can use lower power, lower cost lasers to achieve the same power density in a thin line; providing major savings.

Laser 532nm, line 64mm x 28um

Laser 355nm, line 100mm x 11um

Profile along laser line

Diffractive solution advantages:

- Easy alignment and installation.

- Extremely high precision for beam quality transformation, achieved by the lithography production process.

- A fully transmissive (no reflection), on-axis system.

- Aberration free.

- Can be easily modified to produce different line lengths and widths.

- No internal focus points.

- Available in a wide spectral range from DUV to NIR.

The solution includes two modules:

- The first module is M2 transformation module. It is used for beam quality transformation and thin line beam shaping.

- The second module is used for line length control and focusing in the narrow axis.

Applications:

- Laser lift off processes & debonding.

- Laser annealing.

- Laser Welding.

- Thin-film solar cell production.

- Direct laser interference patterning (DLIP).

- OLED displays.

Materials:

Processing of a broad range of materials including:

- Silicon.

- Silicon on glass.

- Polymers.

- ITO on glass.

Typical Specifications:

| Wavelength: | 343,355, 532 [nm] |

| Input M2: | 12-25 |

| Line length: | On demand |

| Line uniformity: | <5% |

| Line thickness FWHM: | < 20 [um] |

| Efficiency: | > 75 % |

| Working distance: | 125 [mm] |

| Energy density at sample: | Laser power dependent |

| Dimensions: | TBD |

| Full System length: | TBD |