Please enter your laser wavelength and use the filter products below.

Moreover, for a quick quotation for products you see in the table, please check all the desired PNs at the last column of the table and click on the RFQ calculator icon at the column title.

Need shorter lead time? Lead time of uncoated DOE is 5 weeks shorter! Click here for questions.

| PN | λ [nm] | Beam Dia [mm] | Image Shape | θf [mRad] | Image size [um] EFL=100mm | Availability | Remarks | Add to Quote |

|---|---|---|---|---|---|---|---|---|

| MR-001-I-N-A | 1064 | 8.5 | Round | 4.26 | 426 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.5

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:4.26

Transfer Region [mRad]:0.13

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-001-I-Y-A | 1064 | 8.5 | Round | 4.26 | 426 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.5

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:4.26

Transfer Region [mRad]:0.13

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-002-I-N-A | 1064 | 4.5 | Round | 0.52 | 52 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.5

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.52

Transfer Region [mRad]:0.098

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-002-I-Y-A | 1064 | 4.5 | Round | 0.52 | 52 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.5

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.52

Transfer Region [mRad]:0.098

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-003-I-N-A | 1064 | 5.3 | Round | 0.44 | 44 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:5.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.44

Transfer Region [mRad]:0.084

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-003-I-Y-A | 1064 | 5.3 | Round | 0.44 | 44 | 6 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:5.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.44

Transfer Region [mRad]:0.084

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-004-I-N-A | 1064 | 5.7 | Round | 0.40 | 40 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:5.7

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.40

Transfer Region [mRad]:0.077

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-004-I-Y-A | 1064 | 5.7 | Round | 0.40 | 40 | 6 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:5.7

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.40

Transfer Region [mRad]:0.077

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-005-I-N-A | 1064 | 7.9 | Round | 0.29 | 29 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7.9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:20

Clear Aperture [mm]:18

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.29

Transfer Region [mRad]:0.055

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-005-I-Y-A | 1064 | 7.9 | Round | 0.29 | 29 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7.9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:20

Clear Aperture [mm]:18

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.29

Transfer Region [mRad]:0.055

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-006-I-N-A | 1064 | 10.2 | Round | 0.23 | 23 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:10.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.23

Transfer Region [mRad]:0.043

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-006-I-Y-A | 1064 | 10.2 | Round | 0.23 | 23 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:10.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.23

Transfer Region [mRad]:0.043

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-007-I-N-A | 1064 | 6.8 | Round | 0.34 | 34 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6.8

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.34

Transfer Region [mRad]:0.065

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-007-I-Y-A | 1064 | 6.8 | Round | 0.34 | 34 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6.8

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.34

Transfer Region [mRad]:0.065

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-008-I-N-A | 1064 | 9 | Round | 0.26 | 26 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.26

Transfer Region [mRad]:0.049

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-008-I-Y-A | 1064 | 9 | Round | 0.26 | 26 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.26

Transfer Region [mRad]:0.049

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-009-I-N-A | 1064 | 11.3 | Round | 0.21 | 21 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:11.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.21

Transfer Region [mRad]:0.039

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-009-I-Y-A | 1064 | 11.3 | Round | 0.21 | 21 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:11.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.21

Transfer Region [mRad]:0.039

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-010-I-N-A | 1064 | 2.3 | Round | 1.02 | 102 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:2.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.02

Transfer Region [mRad]:0.19

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-010-I-Y-A | 1064 | 2.3 | Round | 1.02 | 102 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:2.3

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.02

Transfer Region [mRad]:0.19

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-011-I-N-A | 1064 | 3.4 | Round | 0.69 | 69 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:3.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.69

Transfer Region [mRad]:0.13

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-011-I-Y-A | 1064 | 3.4 | Round | 0.69 | 69 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:3.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.69

Transfer Region [mRad]:0.13

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-012-I-N-A | 1064 | 8.4 | Round | 1.03 | 103 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:20

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.03

Transfer Region [mRad]:0.11

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-012-I-Y-A | 1064 | 8.4 | Round | 1.03 | 103 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:20

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.03

Transfer Region [mRad]:0.11

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-013-U-N-A | 1064 | 4.2 | Round | 13.32 | 1332 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:7.5

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:13.32

Transfer Region [mRad]:0.43

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-013-U-Y-A | 1064 | 4.2 | Round | 13.32 | 1332 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:7.5

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:13.32

Transfer Region [mRad]:0.43

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-014-Q-N-A | 1064 | 4.2 | Round | 10.13 | 1013 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:7.5

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:10.13

Transfer Region [mRad]:0.27

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-014-Q-Y-A | 1064 | 4.2 | Round | 10.13 | 1013 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:7.5

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:10.13

Transfer Region [mRad]:0.27

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-015-U-N-A | 1064 | 4.2 | Round | 6.06 | 606 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:6.06

Transfer Region [mRad]:0.25

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-015-U-Y-A | 1064 | 4.2 | Round | 6.06 | 606 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:4.2

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:9.2

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:6.06

Transfer Region [mRad]:0.25

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-016-I-N-A | 1064 | 7 | Round | 3.32 | 332 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:3.32

Transfer Region [mRad]:0.15

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-016-I-Y-A | 1064 | 7 | Round | 3.32 | 332 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:3.32

Transfer Region [mRad]:0.15

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-017-U-N-A | 1064 | 8.4 | Round | 0.47 | 47 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:21

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.47

Transfer Region [mRad]:0.11

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-017-U-Y-A | 1064 | 8.4 | Round | 0.47 | 47 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:8.4

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:21

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.47

Transfer Region [mRad]:0.11

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-018-Q-N-A | 1064 | 6 | Round | 3.21 | 321 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:15

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:3.21

Transfer Region [mRad]:0.17

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-018-Q-Y-A | 1064 | 6 | Round | 3.21 | 321 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:15

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:3.21

Transfer Region [mRad]:0.17

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-019-I-N-A | 1064 | 7.9 | Round | 0.29 | 29 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7.9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.29

Transfer Region [mRad]:0.055

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-019-I-Y-A | 1064 | 7.9 | Round | 0.29 | 29 | 6 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:7.9

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22.9

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.29

Transfer Region [mRad]:0.055

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-020-Q-N-A | 1064 | 6 | Round | 1.51 | 151 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:20

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.51

Transfer Region [mRad]:0.15

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-020-Q-Y-A | 1064 | 6 | Round | 1.51 | 151 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:20

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:1.51

Transfer Region [mRad]:0.15

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-022-I-N-A | 1064 | 6 | Round | 0.73 | 73 | In Stock | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:15

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.73

Transfer Region [mRad]:0.14

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| MR-022-I-Y-A | 1064 | 6 | Round | 0.73 | 73 | 7 weeks | ||

|

Input Parameters

Wavelength [nm]:1064

Required Beam Diameter at 1/e2 [mm]:6

Beam Mode (SM/MM):Single Mode TEM00 with M^2<1.5

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:15

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:0.73

Transfer Region [mRad]:0.14

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-232-I-N-A | 1064 | >1.5 | Round | 34.90 | 3490 | In Stock | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:1.5

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:8.8

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:34.90

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-232-I-Y-A | 1064 | >1.5 | Round | 34.90 | 3490 | 7 weeks | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:1.5

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:11

Clear Aperture [mm]:8.8

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:34.90

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-247-I-N-A | 1064 | >6 | Round | 8.73 | 873 | In Stock | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:6

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:23.6

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:8.73

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-247-I-Y-A | 1064 | >6 | Round | 8.73 | 873 | 7 weeks | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:6

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:23.6

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:8.73

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-254-I-N-A | 1064 | >4 | Round | 17.45 | 1745 | In Stock | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:4

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:20

Clear Aperture [mm]:18.2

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:17.45

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-254-I-Y-A | 1064 | >4 | Round | 17.45 | 1745 | 7 weeks | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:4

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:20

Clear Aperture [mm]:18.2

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:17.45

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-309-I-N-A | 1064 | >1.5 | Round | 34.90 | 3490 | In Stock | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:1.5

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22

Thickness [mm]:3

Coating:Uncoated

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:34.90

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

| RD-309-I-Y-A | 1064 | >1.5 | Round | 34.90 | 3490 | 7 weeks | MM | |

|

Input Parameters

Wavelength [nm]:1064

Minimum Beam Diameter [mm]:1.5

Beam Mode (SM/MM):SM or MM

Element Parameters

Element Type:Window

Material:Fused Silica

Element Size [mm]:25.4

Clear Aperture [mm]:22

Thickness [mm]:3

Coating:AR/AR coating

Output Parameters

Output Shape:Round

Full Angle at 1/e2 [mRad]:34.90

Transmission efficiency:Close to 100%

Overall Efficiency:~ 0

|

||||||||

Need shorter lead time? Lead time of uncoated DOE is 4 weeks shorter!Click here for RFQ and questions

|

||||||||

Loading, Please Wait...

Holo/Or offers Diffractive Optical Elements in a wide variety of wavelength between 180nm and 11um

For DOE solutions outside this range, please contact us for custom solutions.

| Materials | Fused Silica, ZnSe |

|---|---|

| Wavelength range | 193nm to 10.6um |

| Full angle | Large range of full angles |

| DOE design | 2-level (binary) to 16-level |

| Diffraction efficiency | 86% - 96% |

| Element size | Few mm to 150mm |

| Coating (optional) | AR/AR Coating |

| Custom Design | Almost any size |

Features:

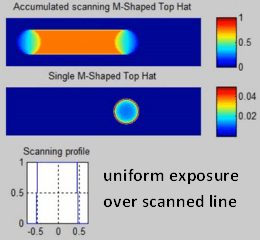

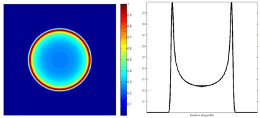

- Round M-Shape output profile (before integration)

- Uniform exposure over scanned lines

- Clearer defined edge

- High efficiency

- High power threshold

- Wavelengths from UV to IR

- Optional Ar/Ar coating

Applications:

- Laser materials processing:

- welding

- cutting

- scribing

- Strong weld seams (also in Plastics)